#Spinning

The new Weftmaster SFB

Redesigning our future

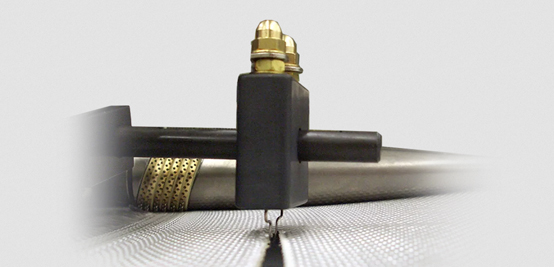

Protecting goods from adverse weather and other factors helps to ensure satisfied end-customers. Loepfe's WeftMaster SFB-L yarn brake is the perfect system for producing these coated technical fabrics on projectile and rapier looms in the most economical way.

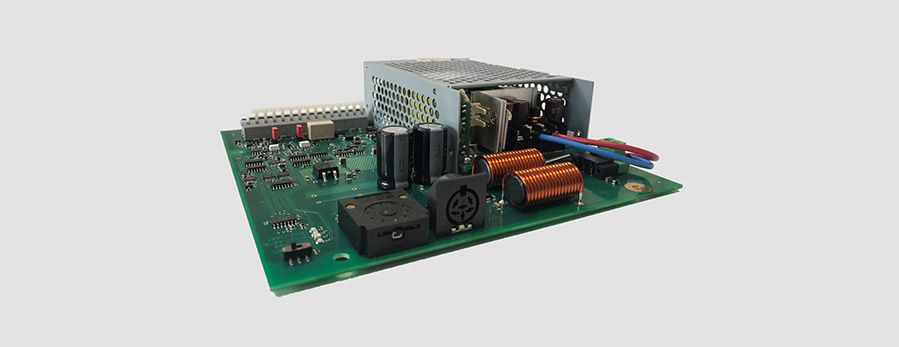

The WeftMaster SFB weft brake has been in use on projectile and rapier weaving machines worldwide for many years. Since its foundation in 1955, Loepfe has been a reliable, expert partner to the weaving industry. Still today Loepfe remains totally committed to the further development of its various weaving products. For instance, the control electronics for the SFB weft brake were recently redesigned for the future. The new electronics can now control 4 brakes instead of the previous 3, which saves space and simplifies the brake deceleration setting. In addition, the inputs are now also galvanically isolated.

Projectile looms are designed for the production of a wide variety of fabrics and are considered to be space-saving, especially when producing heavy fabrics. Thus the applications are almost endless, especially in the field of technical textiles. The focus is always on the high-quality requirements of the various end-products. Especially when yarns with a low tensile strength are used, weft tension is a decisive parameter.

Too much stretching can lead to uneven fabric or - in the worst case - to weft thread breaks, which lead to expensive machine stoppages. Therefore, a constant, even weft thread tension is essential for all yarn types.

By using the WeftMaster SFB electronic weft thread brake, the number of weft breaks can be reduced by at least 50%. Its use pays off for the weaving mills within a very short time and significantly improves the quality of the fabric. Every weft break is a potential source of error (including start-up faults, the formation of stripes, etc.).

You can find more information on how the WeftMaster SFB weft brake increases machine efficiency here [Know-How].

The WeftMaster SFB weft brake is in use for the production of:

- Tarpaulin fabrics for trucks, advertisements, agriculture and architecture

- Filter fabric, e.g. for water filtration or also paper production

- Geotextiles

- Screen prints

- Canvas

- Conveyor belts, straps

- Blood filters

- Microphone filters for mobile phones

- Speaker filters for mobile phones

- Carbon fiber fabrics for auto parts

- Carpet backing

- Bigbags

- Potato bag fabrics

- Silk fabrics for underwear

- Wool fabrics for suits

The requirements of the different fabrics are highly varied and weaving mills often depend on individual solutions. In this awareness, Loepfe offers its customers suitable solutions for all types of projectile and rapier weaving machines. Furthermore, weaving mills can always count on the straight-forward and quick assistance of Loepfe experts.