#Spinning

New R&D lead appointments at Loepfe

To lead the Loepfe R&D team, the company has installed a double-lead consisting of Thomas Schlegel who has strong know-how in hardware, electronics, production quality and project leadership, together with Roger Hilzinger who has been leading the Loepfe software group over the past three years. The two appointments are made to replace Lorenzo Occhi who will leave Loepfe after thirteen years, eight of which were spent as Head of R&D.

Roger has been working for Loepfe for a total of nine years and is well acquainted with the applications for Loepfe products in the textile market. He is an engineer with a Diploma Degree in Information Technology from Zürich University of Applied Sciences (ZHAW) and a Certificate of Advanced Studies in Leading Engineers from Kaleidos University of Applied Sciences Switzerland.

Thomas has a strong track record in project management and development of state-of-the-art hardware and sensor technology, as he has also held deputy head of R&D and quality management roles in the past. He has a Diploma in Electrical Engineering from Hochschule für Technik Rapperswil, a Master of Advanced Studies in Business Engineering Management from Fachhochschule Nordwestschweiz, and various training certificates including the INSEAD Leadership certificate.

Roger Hilzinger said: “I’m looking forward to work with Thomas. We get on really well and complement each other perfectly. We are lucky to work in Loepfe’s motivated and experienced R&D team. I am convinced that in future we will make our products even better so that our customers will benefit more, given the context of digitization and industry 4.0.”

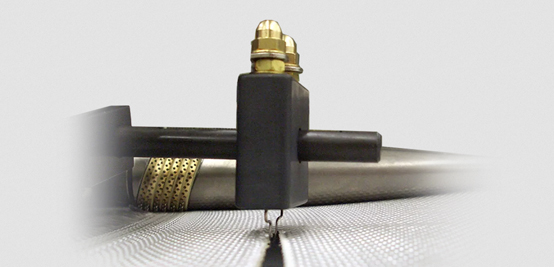

Thomas Schlegel added: “When I was asked to take over the R&D lead at Loepfe together with Roger I was immediately enthusiastic as the two of us have worked very well together during the development project of the YarnMaster PRISMA clearer that has been launched recently. I look forward to develop even more revolutionary products with the team for our customers’ requirements and for a really bright future for Loepfe.”

Loepfe CEO Dr. Ralph Mennicke commented: “On behalf of Loepfe, I would like to take this opportunity to thank Lorenzo for his valuable contributions to product development as well as company management. R&D is a key driver of product innovation and disruptive approaches in a product and solution company like Loepfe. It was a natural decision – and a great pleasure – to promote both Thomas and Roger to jointly success Lorenzo in heading the Loepfe R&D team. Roger and Thomas complement each other with their strong technical domain knowledge in hardware and software, respectively. Congratulations to both of them!”