#Spinning

Oerlikon publishes first-quarter 2020 results and implements comprehensive actions to navigate current COVID-19 Pandemic

- The COVID-19 pandemic has impacted the world economy, businesses and daily lives in an unprecedented manner. Oerlikon has taken actions to protect employees while maintaining business continuity.

- Oerlikon continued to have a very robust capital structure with a strong cash position and an unlevered balance sheet and is executing an action plan to preserve cash and reduce costs in all businesses.

- Q1 Group order intake, sales and EBITDA were negatively impacted by the COVID-19 pandemic due to the extended shutdowns in China and the beginning of lockdowns in Europe.

- Manmade Fibers Segment Q1 orders were impacted by the lockdown and the extended Chinese New Year in China. The current assessment is that the 2020 planned delivery schedules for the segment will be maintained; new contracts exceeding CHF 600 million were awarded, with deliveries in 2022/2023. Global demand for meltblown technology used to produce surgical face masks is increasing.

- Surface Solutions Segment Q1 performance was impacted by the slowdown in all end markets; the previously announced productivity program continued with aggressive cost-cutting targets to increase efficiency and agility.

- Oerlikon is withdrawing guidance for the full year 2020 due to the high degree of market uncertainty; Oerlikon remains committed to the mid-term target for Group EBITDA margin of 16% – 18%.

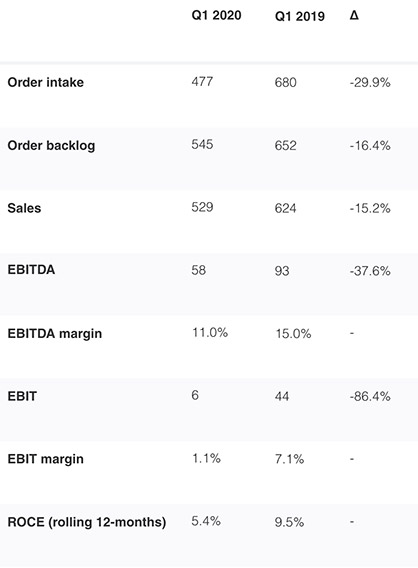

Key figures of the Oerlikon Group as of March 31, 2020 (in CHF million)

“Since the beginning, ensuring the safety and well-being of our employees, customers and suppliers has been our utmost priority,” added Dr. Fischer. “In these uncertain times, our businesses have been experiencing dynamically evolving business conditions. China has shown signs of overcoming the virus, in particular in our manmade fibers business, while we faced increasing challenges from the global impact in our Surface Solutions Segment toward the end of the first quarter in Europe and in the USA.”

“Our manmade fibers business continues to be very well positioned, driven by long-term, strategic customer investments in the filament value chain in China. As a result of the COVID-19 pandemic, we are seeing strong global demand for our meltblown technology that is used to produce surgical face masks. To support this demand that is expected to further grow, we have ramped up our production capacity and significantly reduced delivery times of these systems. In addition to selling our equipment globally, we are supporting local and international businesses with nonwoven materials. For example, we are now producing in Germany more than 100 000 m2 of fabrics per month for the manufacture of over one million face masks each month to protect lives,” supplemented Dr. Fischer.

“As we cannot predict the duration and scope of the spread of the virus, we are withdrawing our guidance for 2020. Our focus remains on executing the measures to protect our business and stakeholders in the near term, while preparing for the return to normalcy and remaining committed to our mid-term ambitions,” concluded Dr. Fischer.

Q1 Results impacted by COVID-19 Pandemic

The scale of the COVID-19 outbreak resulted in the World Health Organization’s declaration of the virus as a pandemic on March 11, 2020. Since then, the crisis has affected every facet of corporate, social and daily lives worldwide in unprecedented ways. With production and business shutdowns in a large number of countries, the crisis has severely impacted many industries, resulting in the postponement of and declines in investments in equipment and services.

In this highly challenging environment, Group orders for the first quarter decreased by 29.9% to CHF 477 million, particularly in Asia and Europe. Group sales were 15.2% lower at CHF 529 million, attributed to lower sales across all regions and adverse currency movements. At constant exchange rates, Group sales were CHF 558 million.

Group EBITDA was at CHF 58 million, corresponding to a margin of 11.0%. EBIT for Q1 2020 was at CHF 6 million, or 1.1% of sales. The first-quarter performance resulted in a rolling 12-month Oerlikon Group ROCE of 5.4%. In the first quarter of 2020, Oerlikon generated 42.0% of total Group sales (Q1 2019: 40.4%) from services.

Strong mitigating measures to protect liquidity and business continuity

In February, Oerlikon proactively started implementing an action plan to mitigate the impact of the pandemic. The action plan focuses on preserving the liquidity of the company, while ensuring that its businesses continue to operate and customers’ needs are met.

Oerlikon has reinforced its strong cash position by proactively drawing down its revolving credit facilities. As of March 31, 2020, the Group has a cash balance of CHF 1.0 billion and a net cash position of CHF 219 million. The strong cash position will enable Oerlikon to manage any potential liquidity challenges.

The Group will be very selective in deciding on investments to be made in 2020, in line with the target to reduce capital expenditure (CAPEX) and discretionary spend by at least CHF 100 million in total compared to 2019.

As already announced, Oerlikon is executing a productivity program, primarily aimed at reducing structural cost in its Surface Solutions Segment. Across geographies and through a number of current and planned initiatives, Oerlikon is reducing a total headcount in the surface solutions business of approximately 800 employees, or around 10% of the Surface Solutions Segment’s headcount. As previously disclosed, Oerlikon is expecting to invest CHF 25 million to CHF 35 million in the implementation of the entire program, predominantly for severance costs.

Oerlikon withdraws 2020 Outlook. Remains committed to mid-term EBITDA margin target

The global economy and industries are expecting to face significant challenges in the upcoming quarters due to the COVID-19 pandemic. In particular, the end markets of the Surface Solutions Segment are expected to be impacted globally. Following the easing of restrictions in China, production and operations in the Manmade Fibers Segment have been running at full capacity, and the segment is confident of being able to fulfil its delivery schedules for 2020. In view of the high degree of uncertainty as to the scope and duration of the crisis, Oerlikon is withdrawing its guidance for 2020. Oerlikon remains committed to delivering on its mid-term target for the EBITDA margin of 16%-18%.

Manmade Fibers Segment

Key figures of the Manmade Fibers Segment as of March 31, 2020 (in CHF million)

The segment received new large contracts for filament spinning systems from three of the world’s leading manmade fibers manufacturers in China. The three projects have a total value of more than CHF 600 million. A very small proportion of these projects will be recognized in order intake in 2020, and the majority will be accounted for in 2021 and 2022. Despite the new contracts, the segment noted a decline of 51.4% to CHF 144 million in order intake, partly due to the delay in financial clearance in China as a result of the shutdowns.

Sales for the segment decreased by 19.3% to CHF 205 million, attributed to the lockdown in China and to lower demand for equipment and systems for special filament (carpet and industrial yarn) and plant engineering (polymerization, staple fibers and nonwovens), particularly in North America, Europe and Asia. Following lower sales, the EBITDA margin declined to 8.9%. EBIT for Q1 2020 was CHF 11 million (Q1 2019: CHF 27 million) and the EBIT margin was 5.5% (Q1 2019: 10.7%).

In the first quarter, the segment took over the majority stake in Teknoweb Materials s.r.l., which was established in 2017 as a joint venture to extend the nonwoven production system portfolio to include the attractive market for disposable nonwovens. Due to the COVID-19 pandemic, a strong global demand for Oerlikon’s meltblown (nonwoven) technology used to produce surgical face masks has been noted. This demand is expected to grow in the upcoming quarters, driven by government regulations and the need for greater self-sufficiency and reduced reliance on imports for critical medical items. To support this growth, production capacity for the meltblown technology has been ramped up and the delivery times of these systems significantly reduced.

Production in China was closed toward the end of January and in February (extended Chinese New Year and lockdowns). Operations started up gradually in March and have returned to full capacity since the end of that month. Despite the shutdowns in Europe, the segment operated at full speed in Germany, achieving a record production of winders in March in Remscheid, Germany. The key challenge in Europe has been to secure the supply chain in the challenging COVID-19 environment. The segment has succeeded in balancing the situation and is confident of being able to fulfil the planned delivery schedules for 2020. The mid-term outlook for the segment remains unchanged based on current assessment and the project pipeline has been extended, with deliveries reaching into 2023.