#Spinning

Sales revenue declines in the first half of 2019

Mr Clement Woon, Chief Executive Officer, says:

“The first six months of the year proved challenging for the group as we are seeing the delayed impact of the uncertainty resulting from the ongoing trade disputes. Investors are reluctant to invest and since business in our core markets, like China, India and Turkey, are reliant on financing, these factors have had a strong impact on Saurer. Global growth has also slowed down this year.

Another factor that influences the textile industry in particular is ITMA. Being the world’s principal textile exhibition, this event has a profound effect on the market as customers delay orders in anticipation of the new products that manufacturers will launch at the exhibition.

At ITMA 2019, Saurer introduced a number of innovations, including its first air-spinning machine. With the addition of a draw frame to its pre-spinning line, the company is moving another step closer to becoming a complete solutions provider for the textile industry. Also supporting this aim is its new extensive range of laboratory equipment.

While we received very positive response at the exhibition, we cannot be complacent in the current environment. We will work diligently to ensure that Saurer is positioned optimally once the global market returns to previous levels.”

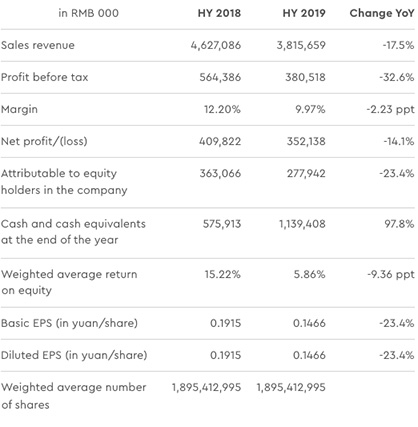

Key financial data

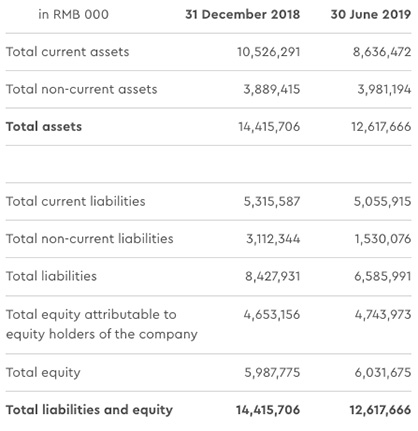

Balance sheet

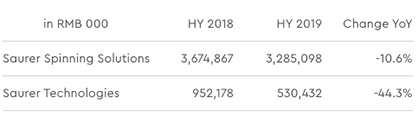

Segment overview

Saurer Technologies experienced a significant decline of 44.3% in the first half of the year. Reasons for this include the exceptional boom in demand for glass fibre, carpet yarn and tire cord in 2017 and 2018 – the resulting oversaturation in the market has negatively influenced Saurer’s twisting business in 2019. Sales declined by 10.6% for the Spinning Solutions segment.

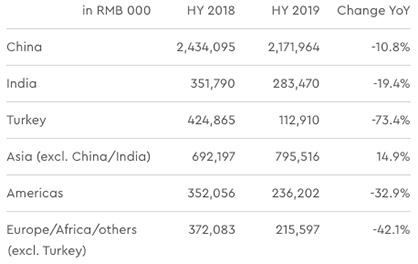

Regional overview

Sales revenue in Saurer’s three largest markets dropped. In China, this meant a decline to RMB 2 171.9 million (-10.8%) while sales in India decreased to RMB 283.4 million (-19.4%). In Turkey revenue fell to RMB 112.9 million (-73.4%). The region Asia (excl. China/India) performed well with a growth in sales of 14.9%, amounting to RMB 795.5 million. Uzbekistan was a major contributor to this result. In the Americas region (-32.9%), performance was mixed, with Mexico seeing good growth while the USA experienced a downturn.

The full half-year financial statement in Chinese is published on Saurer’s website and that of the Shanghai Stock Exchange.