#Research & Development

Wearable Technology: Smart printed sensors monitor movement sequences

In cooperation with Fraunhofer ISIT and with support of the project partners from the industry, the new sensor technology will be incorporated into a prototype shirt. This so-called MONI shirt will feature a number of functions but is foremost designed to monitor movement sequences. In an initial step, Fraunhofer ISC has developed novel piezoelectric polymer sensor printing pastes free from toxic solvents while Fraunhofer ISIT has provided the evaluation electronics. The next development steps are planned in close dialogue with the industry partners. They will include field tests on several types of textiles and applications, the further optimization of the electronics as well as wear and washability tests.

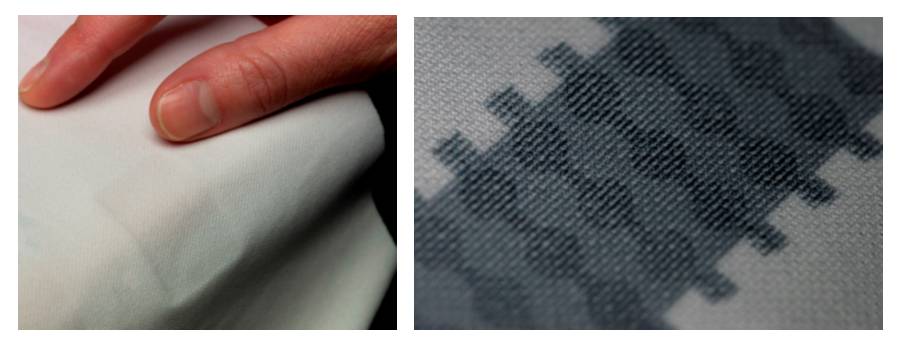

The sensor materials coming to use are flexible, transparent and suitable for various applications also beside of smart textiles: They register pressure and deformation and can thus serve as touch or motion sensors. Their sensitivity to temperature deviations further enables monitoring of temperature changes or non-contact interaction, e. g. as proximity sensors.

A simple screen printing process is all it takes to apply the sensor pastes onto textile fabrics or plastic films. Manufacturing encompasses two steps: First, the pattern is printed.

Thanks to its transparency and flexibility, the new sensor material offers freedom of design in color and form for textiles and garments. As the sensors are much thinner than a human hair and applicable in whatever form, the wearer will hardly notice them embedded in a garment. There’s yet another benefit: the sensors do not require any power source like a battery. Instead, they harvest energy.

Smart textiles like this could be employed in health care or assisted living. In eldercare, everyday life movement sequences could be monitored and failure noticed. Additionally, it would be possible to monitor body signals of in-patients, such as temperature or breathing. This could be especially beneficial for bedridden patients or babies. Some day, even heart rate surveillance may be possible. Last but not least, functional sensor clothing could achieve cost reductions in the health care system. On top of assuming patient monitoring functions it could add to preventive health care.

In Addition to printed sensors on textiles Fraunhofer ISC shows textilintegrated pressure sensors made of silicone e. g. to measure pressure in shoes.