#Research & Development

Water Hyazinth plant pots

Combating an invasive species and reaping economic benefits at the same time? What sounds like a contradiction in terms has been successfully achieved by DITF scientists in a joint project with several companies.

Water hyacinth is a rapidly spreading plant that has been recognized as a threat to existing ecosystems in many countries around the world. In particular, Lake Victoria in Africa is suffering from the widespread spread of water hyacinth. Fish deaths due to oxygen depletion, the production of climate-damaging methane gas during decomposition, and the obstruction of shipping and energy production are among the most prominent problems. They offer a grim preview of what is on the horizon in many other countries. As an invasive species, water hyacinth is spreading into many ecosystems around the world as a result of human activities, threatening the quality of human life.

Several approaches have been taken to control the spread of water hyacinth. The main focus is on removing the carpet of plants from the water and then recycling the resulting biomass. This is also the starting point for the research project co-led by the DITF, which aims to produce a new, cost-effective composite material from the fibrous plant material. The result is a prototype plant pot that is competitive and meets all the technical requirements of the project objectives.

At the beginning of the project, the project partners defined the material requirements for the plant pot. These include good dimensional stability, which must also be ensured when the pot is filled with wet soil. The use of physiologically harmless materials for contact with food plants is also an important requirement, as is a cost-effective and therefore competitive production method. However, the main focus is on complete biodegradability and thus the unrestricted compostability of the plant pot.

The biomaterial for the production of the plant pots comes from Louisiana and is directly marketed by In-Between International under the product name CYNTHIA®. This raw material has been extensively tested and modified at the DITF with regard to its composition and suitability for technical processing. It consists mainly of cellulose and must first be screened and treated with a hydrophobic agent for further processing. Hydrophobing is necessary to give the plant pots a certain resistance to moisture.

The prepared raw material now needs to be combined with a binder. The binder binds the plant fibers and ensures the dimensional stability of the plant pot. Laboratory tests with various binders have identified those that guarantee good processability and dimensional stability of the fiber composite. A thermoplastic was selected that was easy to process in a hot press and that fully met the requirements for biodegradability.

Further laboratory tests determined the ideal ratio of binder to fiber raw material. Tests in an industrial composting plant showed that the material was fully biodegradable and that the plant pots would decompose within a reasonable period of time - a stability of 4-6 weeks was the project goal.

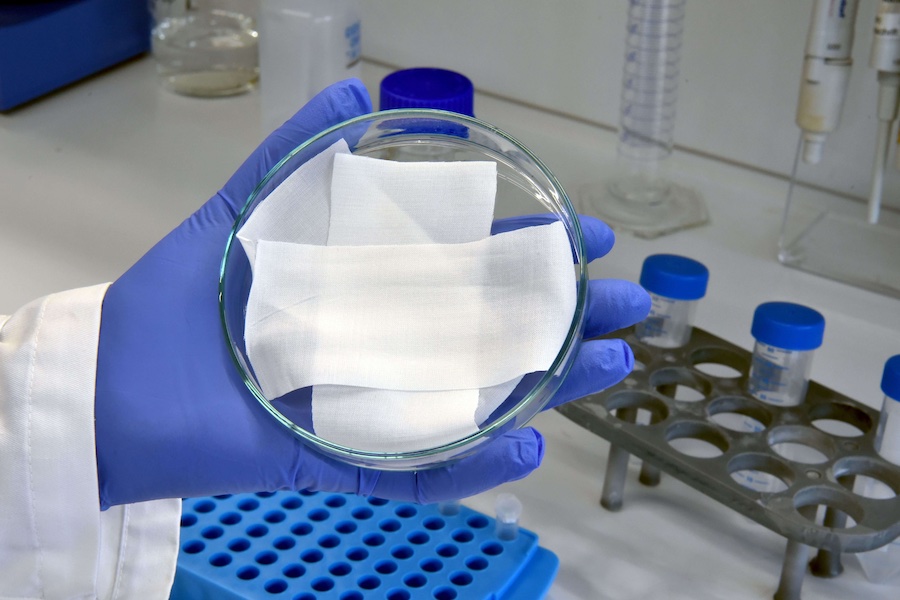

The researchers produced test samples for all these preliminary tests in the form of fiber composite panels on a hot press. The next step was to produce the first prototypes of plant pots from the pre-treated fiber material with the appropriate binder. This part was carried out by the project partner, Fiber Engineering GmbH from Karlsruhe. This company has extensive expertise in the field of fiber injection molding (FIM), which makes it possible to produce 3-dimensional molded parts from fibers in simple and fast process steps. Fiber Engineering GmbH has optimized its existing process for processing the water hyacinth fiber material. It produced a series of plant pots and thus realized the last step of the project objective.

A cost calculation, taking into account all the materials and processes used, confirmed that the plant pots could be produced extremely cheaply at a production price of less than five cents per pot, making them marketable. In daily use, garden centers will appreciate the haptic advantages - strength and moisture resistance despite the fact that the material is completely biodegradable. The fact that the material used is helping to solve a global environmental problem should be another plus when it comes to marketing the product.