#ITMA 2023

Sustainability first - ITA wins second and third prizes in the Research & Innovation Excellence Award in the field of sustainability at ITMA 2023

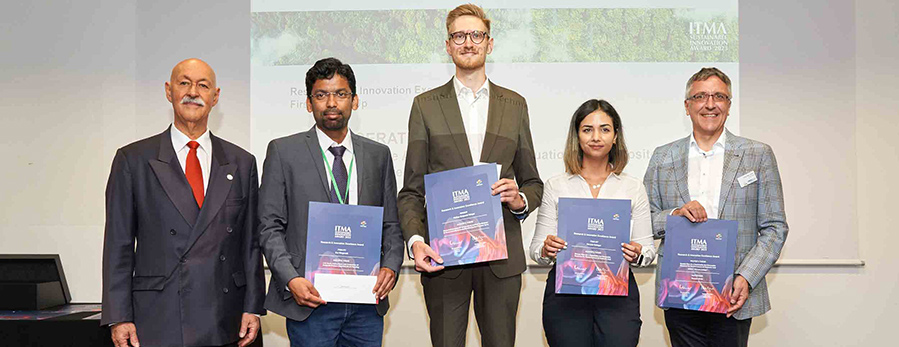

Ms Eva Wingerath, ITA Master's student n (ITA), was awarded second place in the R&I Innovation Excellence Award and prize money of €5,000 for her thesis entitled "Life Cycle Assessment and Evaluation of Composite Pressure Vessel End-of-Life Recycling". ITA PhD student Kumar Jois received the award on behalf of Ms Wingerath.

Maryam Sodagar, ITA Master's graduate and research associate, was awarded third place and prize money of €3,000 for her Master's thesis entitled "Banana Fibres as a Sustainable and Renewable Resource for Reinforcing Polylactic Acid".

Ernesto Maurer, CEMATEX President of CEMATEX, presented the prize money and certificate to the lucky winners during ITMA 2023 in Milan, Italy.

Recovery and reprocessing of carbon fibres improve eco-balance Fibre composites - in high demand and difficult to recycle

The composite market has an annual growth rate of 6.6 percent, leading to a doubled demand within 11 years. About two-thirds of carbon fibre-reinforced composites are based on thermosetting matrices, which makes recycling a challenge. Nevertheless, some methods are developed for recycling of these structures, such as pyrolysis and solvolysis.

Life Cycle Assessment (LCA) reduces environmental impact and meets increasing demand for carbon fibres

The aim of Eva Wingerath work was to evaluate methods for the recycling of carbon fibre-reinforced polymers and implement them in a life cycle assessment (LCA) of a composite pressure vessel. Based on data collected from the manufacturing processes, different mechanical, thermal and chemical recycling methods, and potential applications, a LCA is conducted. Within the framework of this analysis, the environmental impact of the vessel life cycle is calculated, and conclusions about the feasibility are derived. It can be derived that reclamation and remanufacturing decrease the environmental impact and contribute to supplying the need for carbon fibre.

Eva’s work at ITA was supervised by phd-students Tim Mölling and Kumar Jois.

Banana fibres offer sustainable solutions for fibre composite industry - Immense potential for using fibres from food industry waste

Maryam Sodagar‘s work highlights the immense potential of utilizing fibres derived from food industry waste, such as banana fibres, within the composite industry. With an estimated annual worldwide production potential of 300 million tons of banana production waste, this research paves the way for a sustainable and circular approach to material development.

Sustainable solution for the fibre composite industry

Under the supervision of Ms. Anne Hennig, a researcher at ITA, Ms. Sodagar developed a bio-based biodegradable composite material utilising banana fibre as a renewable resource to reinforce polylactic acid (PLA). During her master's thesis, she manufactured various hybrid non-woven based composite materials by combining banana, flax, hemp, and polylactic acid fibres on traditional non-woven manufacturing machinery located at ITA. The approach of using banana fibres to reinforce composites not only addresses the gaps in the banana production value chain, but also provides a sustainable solution for the fibre composites industry.

Continuing her dedication to this field, Ms. Sodagar currently works as a researcher at ITA, where she focuses on further advancing the development and application of bio-based and sustainable composite materials.

ITA wins R&I Excellence Award for the third time in a row

For the third time in a row, ITA graduates have been awarded the R&I Excellence Award.

In 2019, Mathias Zidda won the award for his 3D braiding machine rebuilt according to Industry 4.0 and was supervised by the then ITA PhD student Dr. Martin Kolloch during his Master's thesis "Development of a gear-driven 3D rotary braiding machine and its control concept".

At ITMA 2015, ITA doctoral student Jan Jordan had already won the R&I Excellence Award for his master's thesis "Development & Assembly of a Test Stand for the Analysis of Magnetic Weft Insertion".

The ITMA Sustainable Innovation Award was established by CEMATEX to recognise the collective efforts of the global textile industry to promote corporate sustainability through innovative solutions and to foster outstanding industry-specific research.

The award comprises two categories: an Industry Excellence Award for textile and apparel manufacturers and a Research & Innovation Excellence Award open to Master's students.