#Recycling / Circular Economy

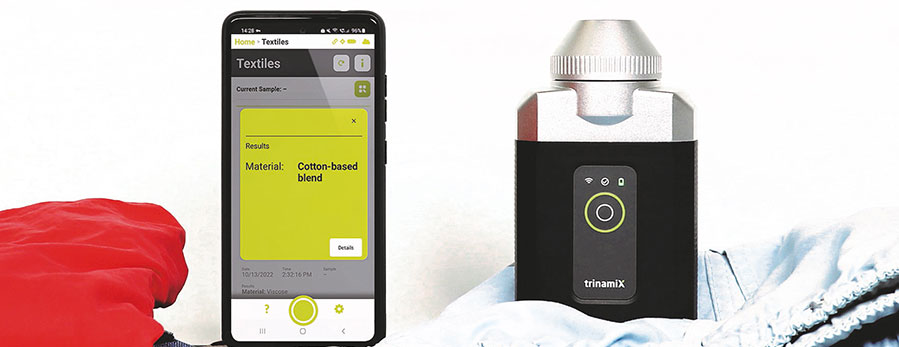

For better recycling of textiles: Reliably identify textile materials on the spot with trinamiX mobile NIR spectroscopy

trinamiX thus opens up new ways for customers from the textile industry to exploit additional potential in the field of textile recycling. Textile collection companies and organizations are equipped with an efficient tool that enables them to pre-sort goods according to quality and next processor. Recycling companies can improve the quality of the recycling process by continuously checking incoming goods. Textile manufacturers also benefit from mobile textile recognition: they can use spot-measurement at goods receipt to check if the delivered textiles are in conformity with the ordered quality.

"We are convinced that innovative solutions like ours make an important contribution towards a circular textile economy," explains Adrian Vogel, Business Development Manager at trinamiX GmbH. "Sorting is a key requirement for recycling and is largely done manually. Even experienced sorters cannot tell the difference between, for example, nylon 6 and nylon 6.6 just by looking at it or feeling it. This is where the handheld solution from trinamiX provides clarity."

The solution supports a wide range of common textile grades used in clothing, furniture and household goods, for example: acrylic, cotton, nylon 6/6.6, polytrimethylene terephthalate (PTT), polyester, polypropylene (PP), silk, sisal, viscose and wool. Textiles made from more than one material can also be identified. These include blends based on acrylic, cotton, nylon, polyester, silk or wool.

For the special requirements of recycling carpets, trinamiX has developed a dedicated application. It supports all common textile and plastic types used in carpets such as nylon 6 and nylon 6.6, polyacrylonitrile (PAN), polyethylene terephthalate (PET), polypropylene (PP), polytrimethylene terephthalate (PTT) and wool. The carpet application is the first one within trinamiX’s Mobile NIR Spectroscopy Solution to work offline. This means that the identification of carpet materials can be carried out when there is no connection to the internet. The data is evaluated and stored directly on the device and smartphone. A later upload to the customer portal is possible without any problems.

trinamiX will present the new applications on November 9 and 10 at two trade shows: Greener Manufacturing Show in Cologne, Germany (booth 5017 in hall 10.1) and Plastics Recycling World Expo in Cleveland, USA (booth 635).