#Recycling / Circular Economy

ATKO Planning realizes leather waste circulation

ATKO collects leather waste from leather tanneries and produces recycled leather yarns and textiles using the world’s first eco-friendly dry processing technology. The company’s recycled leather textile won the grand prize at Premiere Vision Paris 2019, one of the most prestigious events for fashion and textile. It was praised for “the most exceptional, symbolic, and pertinent leather of the season.”

Leather waste used by ATKO is leather scraps collected from LWG Silver and Gold rated leather tanneries. This is why it is possible to produce high-quality leather fibers that enjoy the unique texture and durability of natural leather, unlike the existing regenerated leather that recycles shaving scraps.

Leather scrap is classified as industrial waste because it contains chromium, a heavy metal. Incineration is impossible for this reason, and most are disposed in landfills or dumped in the sea.

However, ocean dumping of leather scrap is becoming more difficult due to a London Convention agreement. While leather scrap accounts for 10% of the world's total waste, only 13.7% of it is recycled. Using ATKO’s recycled leather fabrics will provide a superior solution for manufacturing companies to meet the demands of ESG management without harming the conventional business model that consumes materials and manufactures products.

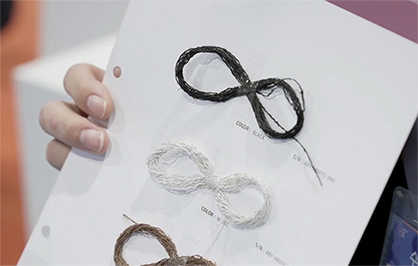

The key technology of ATKO is selecting only high-quality cow leather waste, obtaining recycled leather fibers through the fiberization process, and mixing them with recycled PET fibers to produce spun yarn. It is a dry process that does not use a single drop of water or chemicals, so it is environmentally friendly because it does not discharge wastewater. In addition, ATKO focuses on the circular economy and has already developed continuous resource circular technology to produce futuristic and sustainable products in balance with the environment. Based on it, ATKO can recycle not only leather waste but also ATKO’s products again and again.

Meanwhile, ATKO supplied recycled leather spun yarn to Hyundai Transys’ future mobility seat concept, which was unveiled at the Lineapelle International Leather Fair held in Milano in February. An official from ATKO expressed aspirations that ATKO Planning will take the exhibition as an opportunity as well as accelerate collaboration projects with Hyundai on mobility interior application and prepare mass production supply.