#Recycling / Circular Economy

Respin completes leather waste textile fibre pilot production line

Respin can now begin working towards commercializing the disruptively circular SPINNOVA leather waste fibre. Following the announcement of establishing Respin, a joint venture between Spinnova and KT Trading, in May, the partners now have a pilot production line ready to begin its startup phase. The small industrial scale leather fibre pilot is designed and built by Spinnova, and located in Spinnova’s facilities in Jyväskylä, Finland.?

This means that Respin can start producing larger amounts of the leather fibre for R&D purposes and develop demo products with the material. While the piloting phase is exclusive, Respin joint venture partners will welcome other brands to join the development in its commercial phase. The fibre made of side streams of ECCO’s leather tanneries has great potential in many applications, including footwear.

Setting up a pilot line for leather fibre did not require further technology development from Spinnova. The technology has already been verified in Spinnova’s pilot production line that has been running for 2.5 years using wood-based fibre.

Respin will pay 2.5 million euros to Spinnova for the pilot production line and Spinnova’s R&D services in the course of the proof-of-concept phase. The piloting is estimated to take one year.?– I’m proud of our team for completing the line successfully. We’re all looking forward to upcoming product development with the leather fibre, comments Spinnova’s CEO and co-founder Janne Poranen.

The raw material quality is assured by KT Trading, who specialises in the global sourcing of materials for the leather industry.?– Respin is an excellent example of how far we can get when we work together across industries. We have a joint mission to explore new ways to upcycle our waste material. We’re delighted to take the next steps in this project together with Spinnova and ECCO, says CEO of KT Trading, Kristian Geert-Jensen.

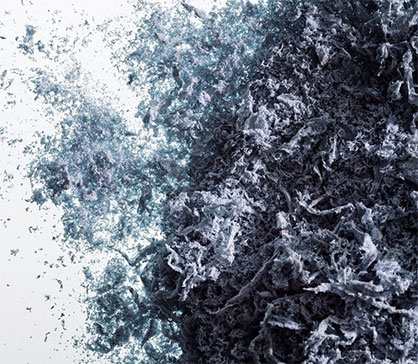

Made with Spinnova’s clean, low-emission tech, the leather fibre’s key sustainability benefits are its use of renewable raw material, zero use of harmful chemicals and minimal water use. The fibre feels like a textile fibre, but it is made from leather waste, combining the natural durability and elasticity of leather and the light weight and feel of traditional textile.

To the partners’ knowledge, they are the only ones in the world to be able to convert leather waste into textile fibre without harmful chemicals.