#Recycling / Circular Economy

NILIT goes circular with SENSIL® Flow

“Our mission to create a more sustainable textile industry requires a shift in mindset throughout the value chain,” says Ilan Melamed, NILIT General Manager. “SENSIL® Flow represents an out-of-the-box approach that directly enables yarn and fabric recycling and lays the groundwork for apparel recycling and is part of a broader circularity mission for NILIT. Such a significant industry transformation can only be attained through deep partnerships that create innovative products and processes, visionary designs, and a collaborative reconfiguration of the value chain itself.”

“According to industry experts, more than 90 million tons of apparel end up in landfills each year,” says Michelle Lea, NILIT’s Chief Marketing and Sustainability Officer. “Only about a fifth of discarded clothing is reused or recycled. The SENSIL® Flow approach eliminates waste throughout the production chain and enables brands to design apparel that lasts longer and, at the end of an extensive life, can be more easily recycled.”

Today, apparel recycling is constrained by the complexity of sorting and separating materials before they can be recycled back to their original components, Garments made with blended fibers and fabrics are especially difficult to recycle.

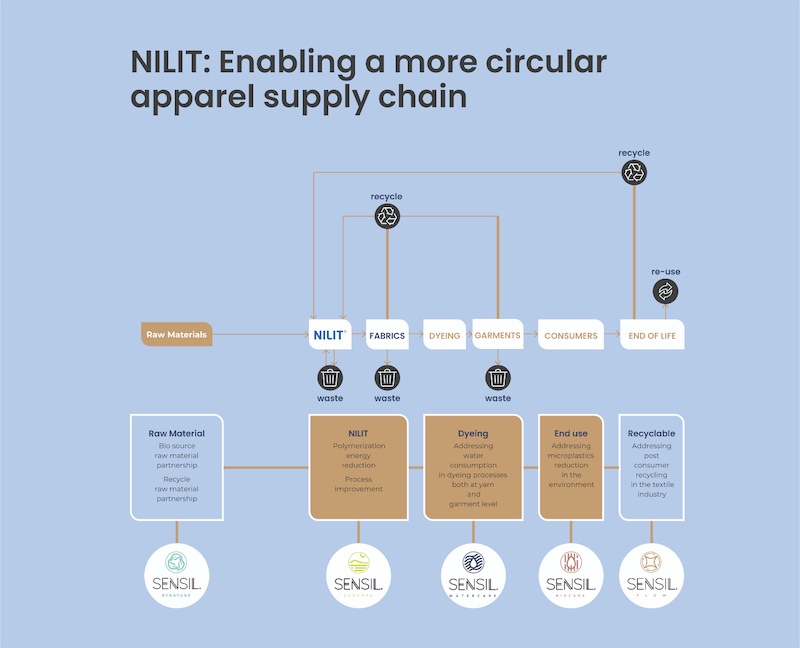

The SENSIL® Flow approach addresses these obstacles on multiple fronts. First, SENSIL® Flow is a yarn that delivers a mono-component fabric with comfort stretch that can be considered as an alternative to elastane in certain end uses. Engineered to provide inherent elasticity and recovery properties, SENSIL® Flow creates comfortable, stretchable performance fabrics for the casual and lifestyle segments. These beautiful fabrics have excellent color absorption and exquisite 3D effects while at the same time making post-consumer recycling possible. Pure premium Nylon 6.6 yarns, fabrics, and garments are easily recycled using a process that requires no additional chemicals and generates minimal CO2 emissions.

Additionally, NILIT partners with recycling experts to facilitate the efficient recovery and recycling of fabric waste and post-consumer fabrics and clothing that would otherwise end up in a landfill or incinerator. These partners are expected to create high quality recycled Nylon chips that can be reintroduced into NILIT’s Nylon fiber spinning process, resulting in high quality outputs, as well as other engineering plastics. Certificates will validate circularity and provide transparency and accountability for partners committed to building a circular textile economy.

Celebrating 50 years of excellence, NILIT offers a comprehensive collection of premium Nylons designed to empower the apparel industry’s shift to a more sustainable position. NILIT launched industry-first SENSIL® ByNature made using bio-gas from reclaimed landfill waste. SENSIL® BioCare is enhanced with a special technology proven to help lessen the persistence of textile waste in sea water and in landfills. SENSIL® EcoCare, crafted with recycled Nylon, improves circularity and LCA. SENSIL® WaterCare with embedded color saves up to 100% of the water used in the traditional wet dyeing process. Plus, the complete SENSIL® portfolio of products is manufactured according to NILIT’s Total Product Sustainability criteria. These responsible yarns give designers the beautiful, environmentally considerate performance fabrics they need to create apparel collections that respond to consumer demands.