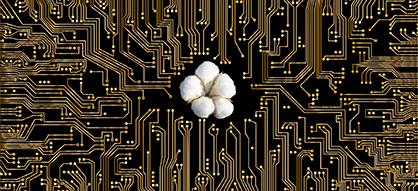

#Raw Materials

Challenges of traceability and raw material quality

- Digital ecosystems

- Effectiveness of locally networked value chains

- What cotton is my t-shirt made of?

- 15 years of CSITC round test: Results and benefits

- Recycling and fibre quality

The European Union is holding textile companies accountable with its planned supply chain law. This requires a rethink in supply chain management. Additional challenges are arising from fast fashion, shorter cycle times in the textile and clothing industry, and demands for transparency and greater sustainability. Questions about the cotton quality required for a product also play an important role in this. The International Cotton Conference will look at methods of traceability and transparency in supply chains, as well as the possibilities for assessing cotton quality in the sessions ‘Traceability’ and ‘Cotton Quality and Testing’. We can expect highly informative lectures and expert discussions which take place on 29 and 30 September.

Digital Ecosystems – The future possibilities!

Gesine Köppe, Research Associate at the Institute for Textile Technology at RWTH Aachen University, will immerse the conference participants in the model of a completely digitally networked ecosystem. It offers complete transparency with the possibility of traceability throughout the entire textile production and supply chain, from the cotton field to the textile and clothing retail trade. According to Gesine Köppe, the solution lies in the use of ‘distributed ledger technology’ with the possibility of targeted documentation of selected transactions, which is also known in a similar form from blockchains. Every participant in the supply chain enters information relevant to the entire network into a decentralised digital ‘main ledger’, just like in bookkeeping. During the project, a permanent documentation and information system will be established to ensure the vertical and horizontal integration of the technologies. The aim is to offer the textile and clothing industry an incentive through cooperation.

Cotton Uzbekistan: Traceability from field to mill

Dr Rinat Gulyaev, Director at the Cotton Science-Innovation Center, Tashkent in Uzbekistan, will present a project aimed at identifying and labelling cotton and cotton products using digital technology. This is intended to create traceability for the participants in the supply chain from the cotton farm to the textile factory. It uses modern international standards and proven procedures. Special emphasis is placed on the interaction of digital technology with other digital platforms in the context of the digital transformation of the Uzbek economy.

Effectiveness of locally networked value chains

Miriam Paris, Bayer Crop Science, USA, will present a special ‘Field to Closet’ project in which cotton grown in Georgia was used in medical products. The special feature: the workwear fabrics are equipped with PROTX2® AV protection from the US company Intelligent Fabric Technologies N.A. This is an antimicrobial technology that inhibits the growth of bacteria, a subject that is of great importance for the medical sector.

Textile tracker: What cotton is my t-shirt made of?

Secured proofs of origin are of essential importance in the textile chain. Karin Ratovo, Research Associate at the Niederrhein University of Applied Sciences, Mönchengladbach, and Markus Bonner Agroisolab GmbH, Jülich, will present the test results of the “Textile Tracker” project. Agroisolab is one of the leading European laboratories in the field of isotope analysis. As part of the research work on the project, they examined whether the chemical signatures of cotton fibres are preserved in the usual textile processing steps. If the validation is successful, it would be possible to set up a georeferenced origin database for cotton and textiles.

15 years of CSITC round test: Results and benefits

Since 2007, the Fibre Institute Bremen has been organising round tests for the standardisation of instrument tests for cotton as part of the Committee on Standardised Instrument Testing of Cotton (CSITC), in cooperation with the International Cotton Advisory Committee (ICAC) and the US Department of Agriculture (USDA). The tests are aimed at verifying and harmonising high-volume instruments (HVI). The results of cotton tests carried out using HVI technology are in demand, for example, in the cotton trade or at spinning mills. Therefore, the testing of a certain cotton quality in certified laboratories should show approximately the same results internationally. Axel Drieling, Senior Manager Cotton and Member of the Board at the Fibre Institute, and the new Head of the CSITC Task Force and Chief Consultant for the Australian company Textile Technical Services, Geelong, Marinus van der Sluijs, will present the progress made in testing over the past 15 years. Van der Sluijs aims to increase the number of cotton processors taking part in the round test. In addition, the advantages of harmonisation and verification for cotton production, trade and spinning mills will be set out and documented with facts.

Recycling and fibre quality

Stephan Baz, Head of the Staple Fibre Technology Department at the German Institute for Textile and Fibre Research, Denkendorf (DIFT) will present the interim results of a project that offers solutions for the evaluation of materials made of cotton or synthetic fibres that are torn for recycling purposes using proven raw material classification. As part of the sustainability debate, the recycling of textiles as part of a circular economy has become a much-discussed topic. The aim of the project is to produce a yarn that is qualitatively usable in the spinning process with the lowest possible loss of properties by optimising the necessary tearing processes.

Fibre quality and ginning

In his second presentation, Marinus van der Sluijs will look at the effectiveness of various ginning processes and individual process stages in the cleaning of seed cotton. At the same time, the effects of these processes on fibre quality were examined.

According to the study, the average dirt content of delivered seed cotton is usually less than 10 percent. During the cleaning process, 20 to 40 percent of the impurities can be removed. Depending on the process, however, essential quality features such as equal length, the proportion of short fibres, the proportion of neps, stretchability, strength, fineness, and maturity vary greatly. When choosing cotton, it is worth taking a look.

Additional Highlights of the Anniversary Week

This year’s International Cotton Conference takes place in a year of celebration for the Bremen Cotton Exchange. The association was founded in 1872 and is celebrating its 150th anniversary. The event is therefore embedded in an entire anniversary week.

The first association and working group meetings will take place in Bremen on 27 and 28 September. These include the International Textile Manufacturers Federation (ITMF), the Discover Natural Fibres Initiative (DNFI), the Industry Association for Finishing - Yarns - Fabrics - Technical Textiles (IVGT), the ICAC Task Force on Commercial Standardisation of Instrument Testing of Cotton (CSITC), a spinning mill and textile seminar given by the Fibre Institute, Cotton Exchange, IVGT and ITMF, and an ICA Bremen Board Meeting. A further highlight is certainly the meeting of the ICAC's Social, Environmental and Economic Performance of Cotton Production (SEEP) expert working group.

Bremen Cotton Night

On the evening of 29 September, the Bremen Cotton Exchange and the Fibre Institute Bremen invite participants to the popular and well-known Bremen Cotton Night. This year, the event is all about the 150th anniversary of the Bremen Cotton Exchange and is taking place in the Bremen Übersee-Museum (Overseas Museum) for a good reason: At the same time, the gates will open to an attractive exhibition on the cultural history of cotton. Conference participants can celebrate in the large atrium of the museum and also take a guided tour of the exhibition. With good music and good food, it will finally be possible to spin personal networks again and at the same time review the multifaceted world of cotton in an exquisite exhibition.

Venue

This year’s conference is not taking place in the historic town hall of the Hanseatic City of Bremen, but at the Bremen Chamber of Commerce in the immediate vicinity of the Cotton Exchange. The Chamber of Commerce has represented the interests of Bremen's trade since 1451 and is closely connected to the Bremen Cotton Exchange.

Early Bird Registration until 18 September

Registration for the International Cotton Conference can be made at any time on the conference website www.cotton-conference-bremen.de. The on-site event is already fully booked, but online participation is still possible. Registration at the low early bird price for online participation has therefore been extended until 18 September 2022.

We will continue to provide information about the International Cotton Conference on 29 and 30 September and the complete programme of the Cotton Week in the form of further press releases and target group-specific newsletters, as well as via our social media channels.

Of course, we cordially invite all interested media representatives to visit the 36th International Cotton Conference. We are happy to support you with accreditation or the selection of suitable discussion and interview partners. We look forward to any form of reporting in the run-up to the conference. We are available for further questions and interviews.

canva-900-1-1-1.jpg)

canva-900-1.jpg)