#Nonwoven machines

Dilo Temafa successfully sells line extension to Eco-Technilin

The machines will complement an existing flax fibre preparation plant in France to enable higher fibre quality.

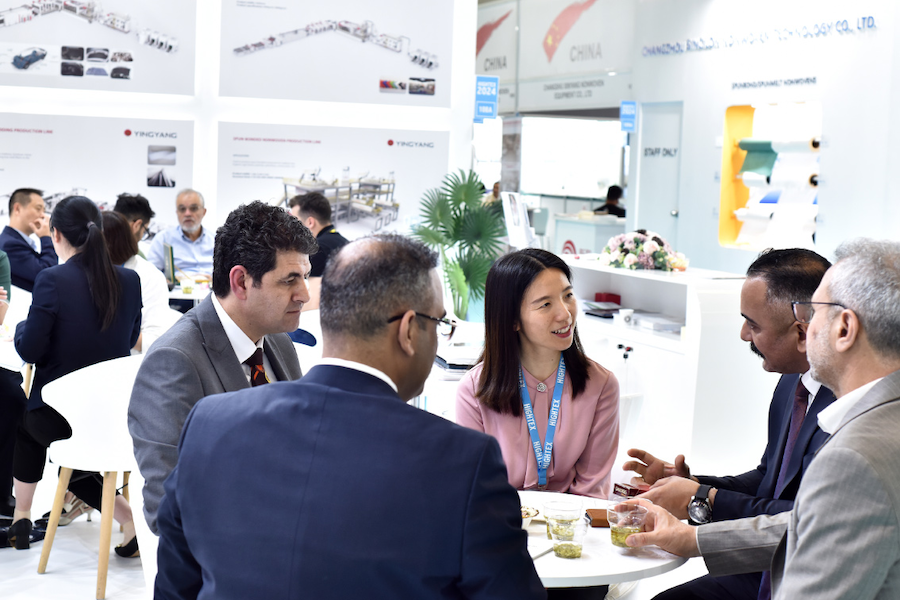

Eco-Technilin, a renowned producer of sustainable materials, has chosen the DILO machines to expand its production capacity and increase its efficiency. The plant expansion is specifically designed to efficiently clean flax scutcher tow and meet the high demands of modern manufacturing, while increasing process stability and plant availability.

Dilo Temafa has been active in the field of natural fibre extraction for more than thirty years and has supplied numerous systems for the processing of bast fibres, e.g. flax and industrial hemp. The fibres obtained are used in various industries, including the construction, automotive, nonwovens and textile industries, and make a major contribution to minimising the ecological footprint.

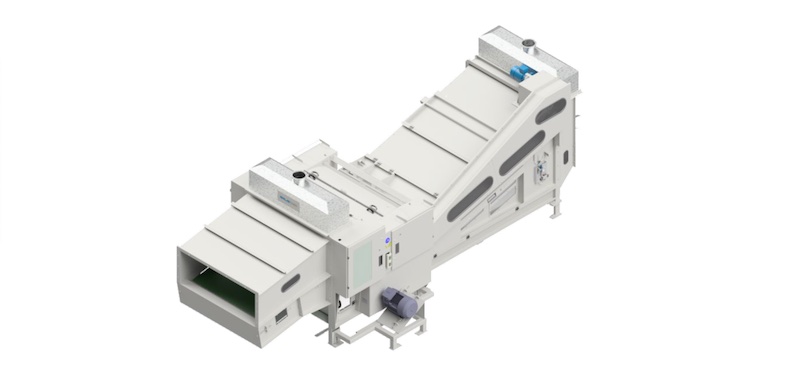

Natural Fibre Preparation - LinLine

TEMAFA developed “LinLine“, the mechanical preparation system for growing natural fibres. Today the Line processes hemp and kenaf, too.

System Specification:

+ Preparation of round and rectangular bales

+ For fibre-containing straw and tow

+ For retted and green material

+ Raw material: bast fibre plants such as flax, hemp, kenaf, jute

The modular design of the line allows a flexible system concept. As such, the type of raw material and the requested quality of the final product will determine the type and number of the individual components.