#Nonwoven machines

ALMA boosts floor covering production with high-performance line from DiloGroup

Their production is mostly dedicated to four different sectors in the market of floor coverings:

• exhibition carpet

• artificial grass

• automotive interiors and car mats

• domestic sector (DIY)

Quality is a decisive factor to respond to the markets’ requirements adequately, as well as competitive pricing. This called for an additional installation of a highly productive state-of-the-art production line from DiloGroup and has been realized by DiloSystems GmbH in Eberbach, Germany.

In a longer phase of engineering, performed jointly among the management of ALMA and the engineering departments of DILO, the required fulfilment of quality, efficiency and economics could be optimized and has led to the ideal choice of state-of-the-art components from fibre preparation, web forming, needling and end-of-line equipment.

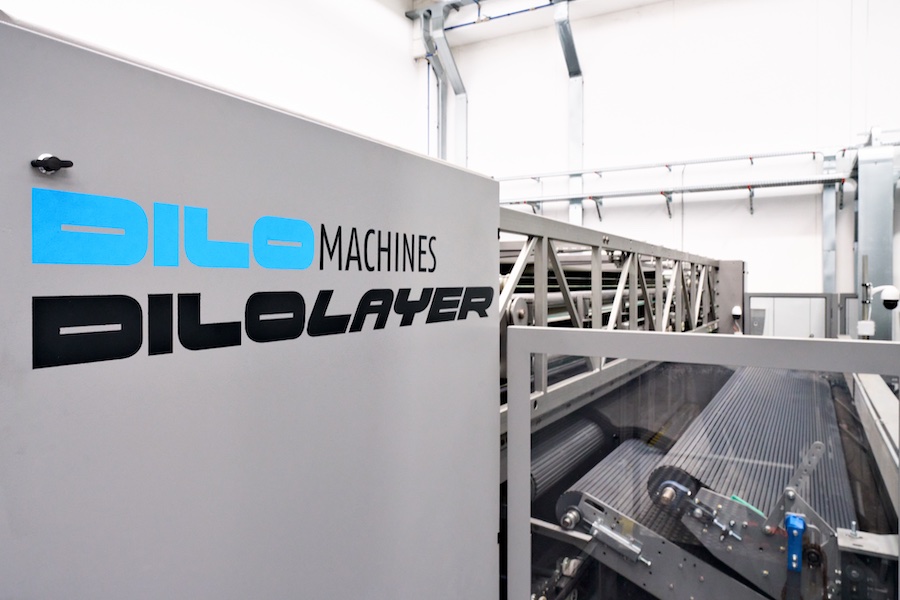

Consisting of a DiloTemafa fibre blending and filtration system, DiloSpinnbau card feeding, state-of-the-art carding, DiloMachines high speed crosslapping, and needling 6 m wide, including inline DI-LOOP for high-speed structuring.

Along with this high-performance preparation, web forming and needling line, modern components of process controls and the Industry 4.0 DI-Connect system according to high level standards have been integrated.

According to the Casini family the line has been installed and started-up in a smooth, straight forward way, synchronizing DILO’s field service and installation team together with the ALMA operating and maintenance department. The launch was providing a quick start-up and is providing full production capacity with the expected features of the renowned ALMA quality.