#Nonwovens / Technical Textiles

Condenser wires for roller cards

Trützschler Card Clothing’s new generation of condensing wires are the solution to this problem in the card’s doffing section. Their unique geometry and premium processing significantly reduce fiber accumulations and ensure the wire’s durability. This empowers our customers to achieve long-term success.

Is frequent condenser cleaning getting on your nerves? Here comes the solution!

What is the problem?

For end products requiring a high-volume web, for instance all kind of wipes, condensing rollers are built into the roller card’s doffing section, with two on the top and two at the bottom. The slow-rotating condensing rollers fold fibers up and thus increase the volume of the nonwoven web. Low-quality condensing roller wires can cause serious wrapping on the roller. That means frequent shutdowns, cleaning and maintenance – which costs time and money, and has a negative impact on the availability and stability of the production process.

What is the solution?

Condenser wires from Trützschler Card Clothing have a proven track record of solving this problem – and they are recognized by customers including Wangjin, Nanfang, Tianlun, Sunshine and many other high-profile companies. Our solutions are able to significantly reduce fiber accumulations because they feature a special combined surface treatment and hardening processes, as well as a unique tooth geometry. Wires from Trützschler Card Clothing help our customers to achieve excellent performance when using roller cards from Trützschler, or roller cards from any other OEM.

Why choose a Trützschler card clothing?

Trützschler Card Clothing offers a wide range of features that provide outstanding performance. This includes:

1. R&D expertise and close collaboration

• 80 years of experience in developing clothing

• Efficient development combined with the Trützschler card and roller card machines

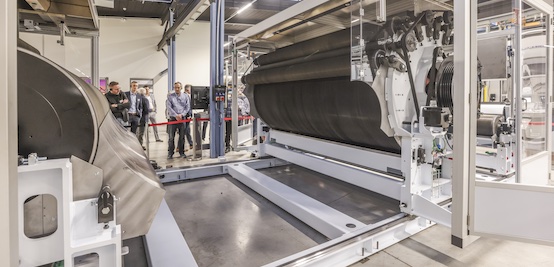

• Precision experiments in the Trützschler Nonwovens Technical Center in Germany

2. Top quality and service life through optimized material base and processing technology

3. Professional, responsive service team and a comprehensive offer of tools and accessories for daily maintenance

Unleashing the maximum potential

TCC offers more than 400 types of wires for every roller on the machine. Customers can select the best possible wire for their needs depending on the roller card configuration, the type of raw material that is being processed, the production rate and several other key process parameters.

When each clothing is correctly selected and well matched, it is possible to achieve the best possible performance of the roller carding machine. And when each individual wire and every interaction between two rollers is perfect, customers are able to unleash the maximum potential of the roller card – and turn a common problem into a unique competitive advantage.