#Nonwovens / Technical Textiles

The Freudenberg House of Sustainability: Sustainability concept with more than 500 sustainable and innovative solutions

With this initiative, Freudenberg is making its entire portfolio of sustainable solutions visible and transparent. At the same time, the leading global manufacturer of technical textiles is also driving its roadmap of forward-looking innovations.

Sustainability has been an integral part of business activities ever since Freudenberg was established and the first values and principles were drawn up in 1887. Freudenberg aspires to reduce its own footprint and increase the handprint for customers and end users. This means the company strives to minimize the impact of its production processes on the environment (footprint) while helping customers achieve their sustainability goals by offering appropriate products and services (handprint).

“Sustainability is a mission and driving force for us. We initiate sustainable programs at global and regional level and are constantly innovating globally available sustainable solutions,” said John McNabb, Chief Technology Officer, Freudenberg Performance Materials. “Many examples bear witness to our forward-looking efforts. To name just a few highlights, we are, for example, pioneers in recycling PET bottles, and commissioned our first recycling plant back in 1991. We developed the first biodegradable nonwoven interlinings in 1995. And today, we recycle more than 2.5 billion post-consumer PER bottles per year.”

“More and more companies and suppliers in the apparel industry today are actively driving change and transparency in sustainability around the globe. Their shared vision is a sustainable future for the apparel industry,” said Jonathan Oh, Senior Vice President & General Manager, Freudenberg Performance Materials Apparel. “As a global leader in apparel interlinings, tapes, canvas and preformed materials, linings and comfortemp® thermal insulations, it is important for us to pioneer in sustainability. With our new House of Sustainability, we want to support this shared vision and innovate for a sustainable future.”

The Freudenberg House of Sustainability

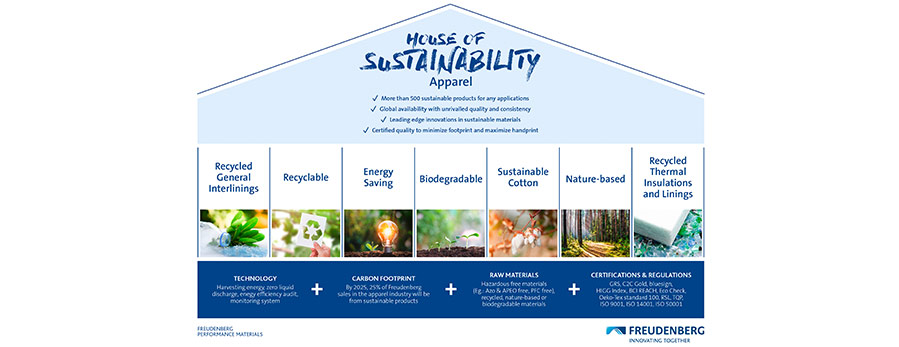

The foundation for the Freudenberg House of Sustainability is made up of four elements: Certifications & Regulations, Raw Materials, Technology and Carbon Footprint. This foundation supports seven pillars providing customers with more than 500 sustainable solutions. The House of Sustainability enables customers to choose the right solutions for their sustainable applications and to meet their sustainability goals efficiently. In addition, all Freudenberg services are visible and transparent.

The 4 elements making up the foundation

Certifications & Regulations

Freudenberg is certified to definitive standards. These include the following: BCI, bluesign®, C2C Gold, ECO-CHECK, Global Recycled Standard, Higg Index, ISO 14001, ISO 50001, ISO 9001, STANDARD 100 by OEKO-TEX®, REACH and Restricted Substances List.

Raw Materials

Freudenberg uses sustainable raw materials to develop solutions. These materials are, for example, free from environmentally harmful substances (Azo & APEO, PFC), recycled, natural-based or biodegradable.

Technology

Freudenberg uses cutting-edge technologies in its manufacturing processes in order to minimize the impact on the environment, such as energy harvesting technologies, zero liquid discharge, and monitoring systems.

Carbon Footprint

Based on its Values & Principles, Freudenberg is committed to reducing its carbon footprint worldwide. The company plans to generate some 25% of its sales in the apparel industry from sustainable products by 2025.

The 7 pillars of the Freudenberg House of Sustainability

Recycled general interlinings

Interlinings made from recycled polyester. By recycling post-consumer PET bottles, Freudenberg is not only minimizing its carbon footprint, but is also helping its customers to manufacture more sustainable garments by choosing sustainable components.

Recyclable interlinings

Interlinings made from 100% polyamide 6. These interlinings can be recycled indefinitely for a consistent closed-loop economy.

Energy-saving interlinings

Interlinings with an innovative adhesive that reduces the fuse-line temperature. This saves energy during fusing and speeds up the fusing process, thereby increasing output.

Biodegradable interlinings & thermal insulations

Thermal insulations and interlinings that are made of cellulose and cotton and are 100% biodegradable in soil. The energy-efficient production process for these interlinings is free from water-endangering raw materials and toxic substances.

Sustainable cotton interlinings

Interlinings made from certified sustainable cotton. Certifications include Cradle to Cradle, Global Organic Textile Standard, Organic 100 and others.

Nature-based interlinings

Interlinings wholly or partly derived from renewable and sustainable sources such as trees, wool, silk, and animal hair such as horsehair.

Recycled thermal insulations & linings

Thermal insulations and linings made from recycled polyester offering premium softness, warmth retention and extreme wear comfort for sportswear.

Launch of the Freudenberg House of Sustainability

The House of Sustainability will be launched worldwide over a 12-week period. Each week, Freudenberg will post in-depth information about the elements and pillars on several channels. The complete House of Sustainability will be presented at ISPO Munich 2022.

Stay tuned and join us on a visit to the House of Sustainability!

Click here to watch the House of Sustainability video.

https://www.youtube.com/watch?v=R4bZEjWYP3w