#Nonwovens / Technical Textiles

A small but powerful nonwovens line for the Hof University in Bavaria

The project of a new trial line at the Nonwovens Development Center (VEZ) at the Münchberg Hof University campus is a good example of how Truetzschler Nonwovens also develops just these types of tailor-made solutions.

The task proved to be both appealing and challenging given that it was very different to the usual industrial projects. In particular, functional planning and space utilization presented a challenge in this regard.

The university team built around professors Ficker, Lottes and Koukal and Mr. Smith required a high level of flexibility for the production of small sample runs. The goal was to produce both spunlaced nonwovens and rolls of thermally bonded material. One thing is for certain: Implementation would have been much simpler in a large production hall than at the new technical center in Münchberg. Nevertheless, the team built around sales expert Enrico Murroni and project manager Leonhard Fleischberger spent hours and hours playing “machine Tetris” in order to cater for the demands of the project in the best possible manner.

Conceptual design, installation and commissioning

After five years of preparation, the conceptual design and layout of the primary machines, the implementation of the secondary installation and the control cabinet setup had been established.

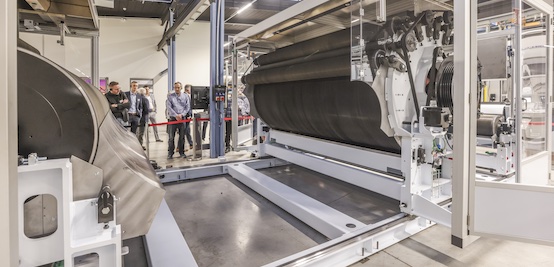

The construction phase and commissioning took place with the restrictions of the corona pandemic in place. Nevertheless, the new nonwovens and carbon fiber technical center was inaugurated on September 25 of last year with the participation of scientists, politicians and economists.

Professors Oliver Lottes and Claus-Ekkehard Koukal agree: “With this research factory, the Hof university at the Münchberg campus has a real flagship project for international textiles engineering education and user research. The full-fledged line supplied by our strategical partner Truetzschler Nonwovens provides industry with the unique opportunity of running series of trials which are close to the production standard.”

About Hof University

The roots of the university go back as far as 1854 when in Hof, in what today is the outermost north east of Bavaria, the cooperative “Hand Weaving School” was founded. In 1994 the Hof University was newly founded and in the year 2000 the Münchberg faculty of Textiles Engineering and Design was integrated. Since 2007 it has been known as the “Hof University for Applied Sciences”.

The institutions stand for roots in the local and regional economy but are also active globally with a focus on India. Since 2005 the university has offered the option of combining studies with a vocational qualification. Almost all study programs can be studied as a dual curriculum and culminate in a vocational qualification together with a degree after four and a half years.

The nonwovens line at the VEZ on the Münchberg campus?

The lightweight nonwovens line is used for teaching, research services and in the practical part of academic work. It includes all components for everything from fiber opening to winding.

Fiber material: Synthetic fibers, such as polyester, polyamide; polypropylene; bicomponent fibers and as cellulose-based fibers, such as viscose or lyocell. In exceptional cases, even fiber blends with high-quality cotton can be processed.

• Nonwoven weights: between 15 and 80 grams/square meter

• Production speed: up to 100 m/min (mechanical)

• Working width: 1,000 mm