#Spinning

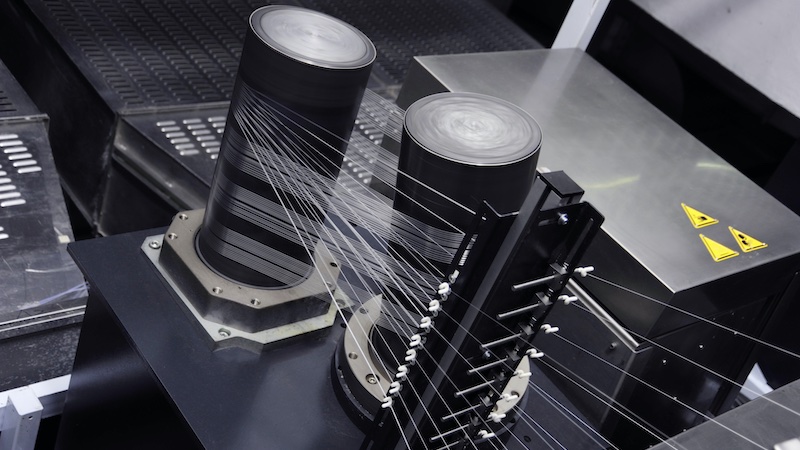

Sinowin commissions first 8-end PA66 tire yarn plant

PA66 industrial yarn specialist expands portfolio

"We believe in the automotive market and its growth opportunities. We believe that industrial yarn has great potential," says Chen Haitao, President of Sinowin. "The automotive industry has extremely high-quality standards. We can reliably meet these requirements with our products, not least because we attach great importance to the quality of our production facilities."

The company has been relying on Oerlikon Barmag technology since it was founded in 2015. Starting with 10 positions, the PA66 specialist has now expanded its capacities to 44 positions. Plans for further capacity expansion and diversification are already in place. "We want to cover the entire tire yarn production chain: Spinning, cabling, weaving and dipping. The entire textile part of the tire from a single source. This will make the tire supply chain much more transparent," says Chen Haitao about his company's plans for the future.