#Knitting & Hosiery

Revolutionizing Knitwear Design with CREATE DESIGN by KM.ON and STOLL

Gateway to 3D Knitwear Innovation

Advantages of the creative process right from the start

The foundation for any knitwear development can be either the structure or the shape. CREATE DESIGN offers the unique flexibility to choose between the structure and the shape as your foundation, thereby allowing to tailor knitwear designs and explore a wide range of possibilities.

CREATE DESIGN goes beyond standard shape design, taking knitting parameters into consideration. It seamlessly converts centimeters into stitches (meshes), and these conversions are dynamically updated if you change your stitch density. This knitwear-centric approach allows for precise and realistic designs.

Next generation stitch development

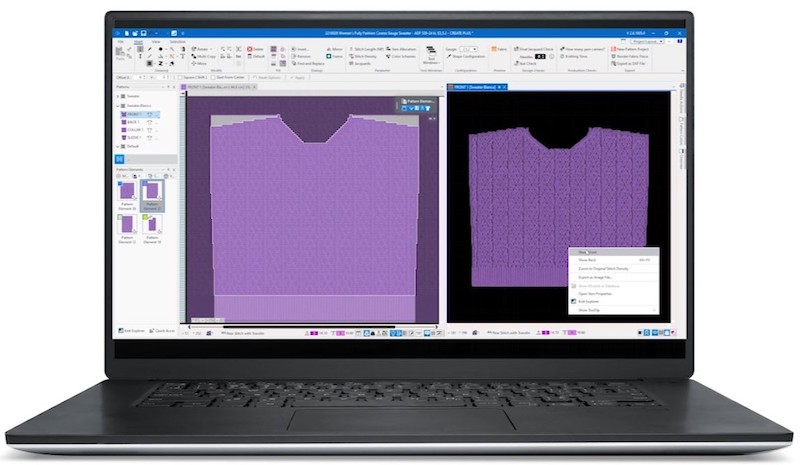

When it comes to Stitch Development, CREATE DESIGN takes the spotlight. The major benefit lies in the software's ability to provide a real-time preview of how the knitwear structure will look. This allows the customer to see his design come to life as he creates it, ensuring that every stitch is in its right place. In addition to the structure preview in real time, there are other useful features.

Versatile Tools for Structure Creation

CREATE DESIGN offers a wide array of tools at disposal to create intricate and unique knitwear structures. Whether crafting delicate textures or complex patterns are in mind, the software provides the flexibility to explore various design elements, helping you unleash your creativity.

Transforming Images into Jacquard or Intarsia Designs

One of the standout advantages of CREATE DESIGN is the ability to import images and seamlessly transform them into captivating jacquard or intarsia designs. This feature enables you to infuse your knitwear creations with personalized images and patterns, setting your designs apart from the rest.

Stitch and Yarn Simulation

One other remarkable aspect of CREATE DESIGN is its ability to simulate stitches and yarn, enhancing the visualization of your designs. The software facilitates digital yarn creation based on optical parameters, giving you a realistic representation of how your design will look in the final product. Then the customer can export these simulations as textures or maps, making it easier than ever to integrate your designs into 3D software for a lifelike rendering.

Export into 3D

Creating your knitwear designs in CREATE DESIGN is just the beginning. The software enables you to seamlessly export your designs into popular 3D software programs, taking your creations to a whole new dimension.

By integrating your designs into the 3D realm, you can visualize your knitwear in a lifelike environment, bringing your vision to life with stunning realism.

The advantages at a glance

CREATE DESIGN isn't just a software; it's an innovative solution for the knitwear industry, and it comes with a multitude of benefits:

• Save Time through Fast Digital Design Development: This software significantly speeds up the design development process, allowing the customer to create stunning knitwear designs with greater efficiency.

• Reduction of Physical Samples: By providing detailed simulations and design previews, CREATE DESIGN helps the customer reduce the need for physical samples, saving costs, labor, and time.

• More Sustainable: Less reliance on physical samples means less waste in production, making the design process more sustainable and environmentally friendly.

• Improved Communication: The software enhances communication between designers and technicians, ensuring that the designers' visions are accurately translated into final products.

“CREATE DESIGN can offer a basis for communication with suppliers thanks to the ability to create designs digitally. It offers the possibility to create many variations of shapes, structures, yarns and colours through a realistic stitch simulation. In this way, the software can support the design process and minimize the number of physical samples," says KM.ON Product Owner Sophie Neff.

Who can use the software?

A large number of users can benefit from the comprehensive advantages offered by CREATE DESIGN.

• Fashion Brands Using 3D Software: Fashion brands using 3D software can seamlessly integrate CREATE DESIGN into their workflow to enhance their knitwear offerings.

• Self-Employed Knitwear and 3D Designers: Independent designers can leverage the software to unleash their creativity and bring their unique knitwear creations to life.

• Knitwear Manufacturers with a Design Department: Manufacturers can streamline their design process, reduce costs, and produce high-quality knitwear with the help of CREATE DESIGN.

• Universities with a Textile or Fashion Degree: Educational institutions can use CREATE DESIGN to train the next generation of fashion and textile designers, providing them with cutting-edge tools to excel in the industry.

In a rapidly changing world, embracing technology like CREATE DESIGN is essential for those who want to remain innovative and competitive in the knitwear market.

Offer from KMON and STOLL for TexData International readers

If you would like to find out more about CREATE DESIGN, you are welcome to request a free, non-binding demo via email at info@kmon.net.