#Knitting & Hosiery

SHIMA SEIKI showcases latest technology in Bangladesh

As the Bangladeshi textile industry calls for sustainable production through innovation and digitalization, the market is keen to establish effective business models that support such production. In response, for the first time in its DTG exhibition history, SHIMA SEIKI's lineup consists entirely of WHOLEGARMENT® knitting machines. Capable of knitting an entire garment in one piece without the need for linking or sewing while using only the material required to knit one garment at a time, WHOLEGARMENT® knitting is famous for promoting sustainability in the knit factory.

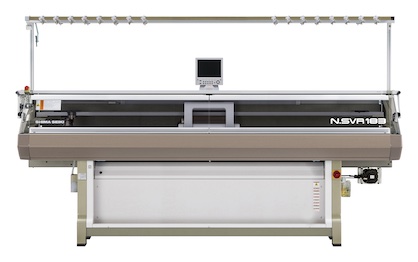

The company is showing its MACH2®XS153 WHOLEGARMENT® knitting machine in 15L gauge, as well as its SWG®091N2 "Mini" WHOLEGARMENT® knitting machine in 15 gauge. MACH2®XS features 4 needle beds and SHIMA SEIKI's original SlideNeedle™, capable of producing high-quality fine gauge WHOLEGARMENT® knitwear in all needles. SWG®091N2 provides opportunities in WHOLEGARMENT® knitting across a wide range of items in a compact, economical package. A different approach to WHOLEGARMENT knitting is also shown in the form of the N.SVR®183 machine. SHIMA SEIKI's global standard in shaped knitting, the N.SVR® series now features a model for producing WHOLEGARMENT® knitwear using every other needle in fine gauge. Shown in 18 gauge at DTG, N.SVR®183 is the ideal machine for flexible, entry-level WHOLEGARMENT® production, with the versatility to respond to fluctuating market demand.

Demonstrations are performed on SHIMA SEIKI's SDS®-ONE APEX4 design system. At the core of the company’s "Total Fashion System" concept, it provides comprehensive support throughout the supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning and design, to machine programming, production and even sales promotion. Especially effective is the way SDS®-ONE APEX4 improves on the product planning

and design evaluation process by replacing physical samples with digital prototypes. Based on photo-realistic simulations, these virtual samples minimize the need for actual sample-making, realizing significant savings in time, cost and material. In combination with WHOLEGARMENT® knitting machines, virtual sampling realizes a sustainable planning and production base.

Exhibit Details

Exhibit: 18th Dhaka International Textile & Garment Machinery Exhibition (DTG 2024)

Date: Thursday, 1st - Sunday, 4th February 2024

Hours: 12:00 Noon - 8:00PM (Final day - 7:30PM)

Location: International Convention City Bashundhara (ICCB)

Kuril Bishwa Road (Next to 300ft. Purbachal Express Highway),

Dhaka 1229, Bangladesh

Tel: +880 (0)2 58970100

Organizer: Chan Chao Int’l Co., Ltd.

Booth No.: Hall 8, Booth 8-343

Exhibited Technology

MACH2®XS153 15L WHOLEGARMENT® knitting machine

SWG®091N2 15G WHOLEGARMENT® knitting machine

N.SVR®183 V18G WHOLEGARMENT® knitting machine

SDS®-ONE APEX4 3D design system