#Knitting & Hosiery

The symmetry makes the difference

Symm-Net à la Chantilly for clothing

Counter-lapping pattern for more clarity

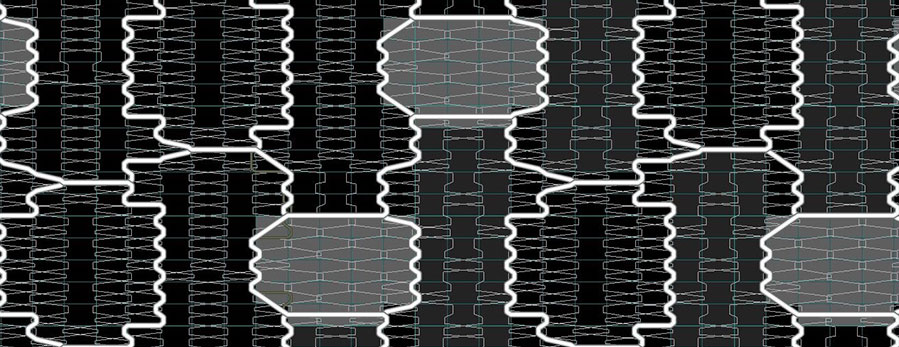

The new MJ 92/1 B multibar jacquard raschel machine is used to produce Symm-Net. Equipped with a split threaded jacquard bar, this newcomer can work both equal- and counter-lapped patterns, and also has two ground bars at the back operating counter-lapped to complete the symmetry. The possibilities of this set-up were exploited in initial samples last year, where Symm-Net was launched in an elastomeric galloon targeted at lingerie. Here a counter-lapping jacquard movement combined with the two counter-lapped elastane bars created a successful symmetry.

Several of the newcomer machines have already been ordered to date.

Rigid Symm-net patterns with fine jacquard structures

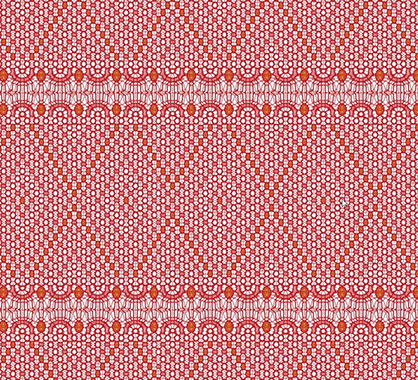

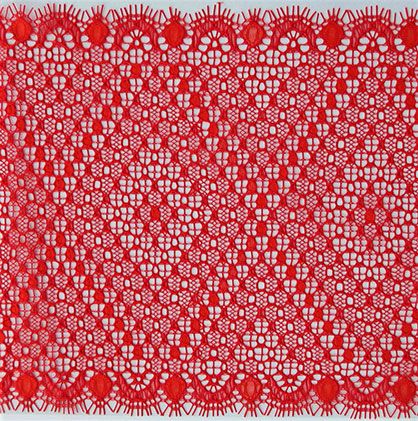

Just in time for the start of the year, KARL MAYER pushed ahead with its Symm-Net developments. Lace expert Jamie Heather created a rigid cross-band galloon for outerwear, relying on a delicate Chantilly-style design. "The advantages of Symm-net are particularly evident in designs with small holes and fine mesh structures," explains the expert. Lightweight lace and in particular Chantilly stylings are now growing in demand, sums up Jamie Heather after his visit to Interfilière in Paris in January. Many manufacturers showed complex designs, clip patterns and classic Chantilly looks in new ways at the leading trade fair. Fine designs incorporating metallic yarns were especially popular.

For the new Symm-Net lace, Jamie Heather has used typical Chantilly yarns - polyamide and 15% cotton for the gimps. The Lace is made as a cross band flounce on the MJ 92/1 B. This means the lace is delivered in three meter strips and is separated by hand. "The fabrics show how symmetrical Chantilly can be, and symmetry is Symm-Net's strength," says the lace expert, explaining his design approach.

Further developments are underway

The new rigid Symm-Net patterns bring pizzazz to garments such as collars, cuffs or inserts, and also attracted attention at Interfilière. "The customers to whom I showed the lace were immediately struck by the visual clarity of the fine mesh structures," says Jamie Heather.

Encouraged by the positive response, he is already working on further Symm-Net developments, including several clip patterns.