#Knitting & Hosiery

Increased productivity with dur sock needles

dur™ can offer even more

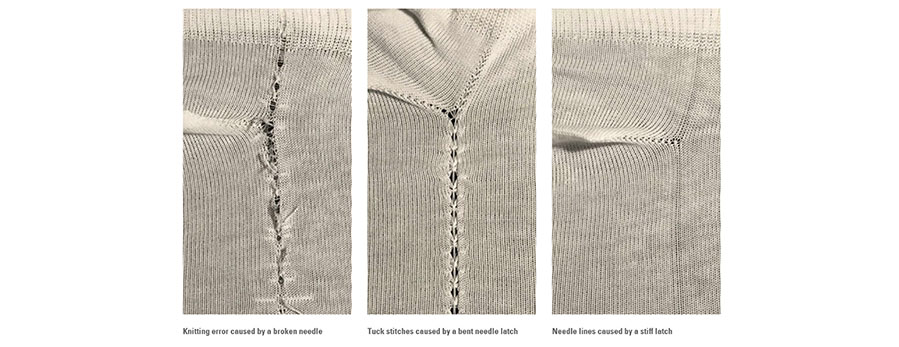

The latest development of the Groz-Beckert sock needles was recently presented under the name dur™. This too was based on feedback received from end users. It is the answer to the increased loads in modern sock production due to fashion or technical aspects. dur™ needles reduce the risk of tuck stitches, needle lines and other faults in the knitted fabric caused by damage to the needle under extreme usage conditions. It is currently demonstrating its effectiveness in the latest machine generations of Lonati and Santoni.

dur™ – the durable

"dur" stands for "durability", i.e. resilience and long service life. Equipped with different properties, needles with dur™ technology are optimally designed for use under higher loads, without compromising the performance of the sock machine.

The technical features at a glance:

- Increased hook stability

- Increased latch stability

- Modified slot design

The higher hook stability reduces the risk of hook breakage and bent open hooks. The increased latch stability and modified slot design reduce the risk of bent latches and also guarantee the latch movement, even with slightly bent latches.

Customer benefits at a glance:

- Lower needle consumption

- Reduced machine downtime

- Increased productivity

- Fewer rejects

- Lower production costs

Field tests in over 50 machines showed a clear reduction in needle consumption, which depending on the application was as low as -30 %. This not only saves costs, but helps to protect the environment too. The reduction of rejects means that the dur™ needle contributes to sustainability.

How to identify dur™ needles

Sock needles with dur™ technology can be identified by the suffix dur™ in the needle designation.

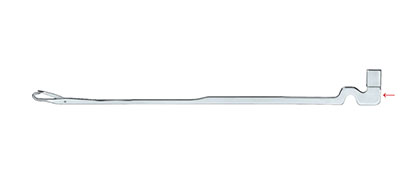

For visual differentiation, dur™ needles have a notch on the back on the butt directly below the predetermined breaking groove.

dur™ needles are currently available for various Lonati and Santoni machine models. The product range can be expanded as required.