#Knitting & Hosiery

Net fabrics with a touch of extravagance

Its commitment to window fashions has two main focuses: transparent, voile-like embroidery grounds, produced on a TM WEFT with the appropriate configuration, and fine fabrics with a woven look produced on the new WEFT.FASHION TM 3 by processing fancy yarns.

Embroidery grounds with an untypical design for typical embroidery

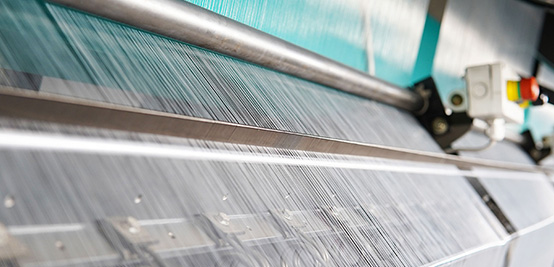

The TM WEFT, with a gauge of E 24, was launched in January 2019 as an innovative new machine for producing interlinings efficiently. KARL MAYER is currently working on a gauge of E 28 for home textile applications. With its finer gauge, this tricot machine with weft insertion is designed to produce fashionable embroidery grounds. Delicate veil-like fabrics with lustrous effects produced by the shimmering yarns can be produced, as well as filigree fabrics with subtle linear designs. This uniform look is based on working different stitch densities and a specific pattern. The TM WEFT works a combination of a pillar stitch, inlay and magazine weft to produce unconventional embroidery grounds. The yarn, which is incorporated over the entire working width, creates a different look and guarantees crosswise stability, which prevents undesirable elongation when the fabric is rotated about an angle of 90° for use as net curtains. More designs can be produced by using different yarns that are easy to process. Jan Hippich says that this concept for the embroidery ground business has been particularly well received by Turkish producers, who are leading this sector. The Head of Product Portfolio Management at KARL MAYER presented the weft-inserted, warp-knitted fabrics for this application at Heimtextil 2019, and had many conversations about them. Many representatives from the weaving sector were also interested. Their leno weaves mean that they are familiar with the look and slip resistance of fabrics produced on the TM WEFT, but they can be produced much more efficiently. Once all the development work had been completed, the TM WEFT, with a working width of 247", should be able to simultaneously produce two net curtain webs, or 120 m of net curtaining per hour. Furthermore, there is generally no need to carry out sizing when producing warp-knitted net curtains. Stylish, on trend fabrics can be produced for an attractive cost. An example can be seen in the pattern part of this issue.

Net curtain designs with special effects

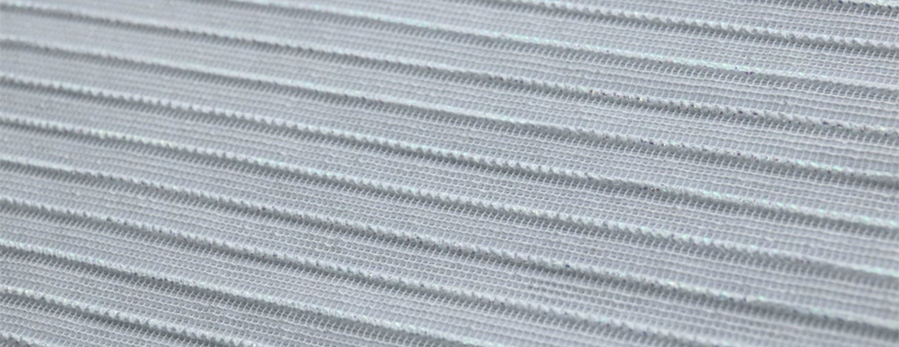

If the pattern effects are not going to be embroidered on, but rather incorporated directly into the net curtaining fabrics, the WEFT.FASHION TM 3 would be the machine of choice. This new tricot machine has three guide bars and can insert medium-weight fancy yarns as magazine weft yarns. “We incorporated more than ten different fancy yarns in the weft zone, and combined them with a ground made from polyester multifilament yarns of 40 den or 50 den. The tests ran perfectly smoothly, and we produced some exceptional patterns,” says Kay Burkhardt from KARL MAYER’s Application Technology Department. Textiles produced on the WEFT.FASHION TM 3 were a real highlight on the company’s stand at ITMA 2019. The delicately patterned fabrics combine fine lattice grounds with a variety of attractive linear designs to create a stylish look that has been a popular feature of woven fabrics for some time. Strict geometrical patterns, as well as irregular, organic structures with a natural look and many other designs can also be produced. Possibilities and new ideas for creations were the subject of many conversations held during the most recent trade fairs. As well as offering a wide variety of different looks, the slip-resistant fabrics deliver all the technological advantages of warp knitting over weaving for producing fabrics, i.e. no sizing process and a higher productivity. Examples can be found in the pattern part of this issue.

The WEFT.FASHION TM 3, a specialist in producing warp-knitted home textiles

The WEFT.FASHION TM 3 is an efficient tricot machine featuring weft insertion in line with the stitches for producing medium- weight home textiles. The machine delivers an exceptional cost:benefit ratio, runs extremely reliably, and is easy to operate. It is available in a gauge of E 24 and with a working width of 132". Net curtain lengths of up to 3.25 m can be worked. The first machines will be delivered at the end this year to a development partner for carrying out practical trials. Production machines will be available for delivery in 2020.