#Industry 4.0 / Digitalization

Digitalization brings movement to the sports, fitness and wellbeing sector

Trends such as fitness lifestyle and vitality, the quantified self movement, active ageing and the outdoor boom will significantly change the sports, health and wellness sector in the coming years. In addition, technical innovations will redefine the way people stay fit and healthy.

The DiMo - Digital Motion joint project aims to help shape the transformation process. It ran in its first round in 2023 and will be continued for another four years with DiMo-NEXT.

The project aims to conduct transdisciplinary research into how people's experience of exercise can be improved, performance increased and a sustainable lifestyle made possible. The potential offered by digital technologies, particularly in the field of sensors, plays a key role here. The topic of clothing is also important as an interface between technological solutions and people. This is why KARL MAYER and Grabher are among the 26 project partners from industry and research, representing the textile industry.

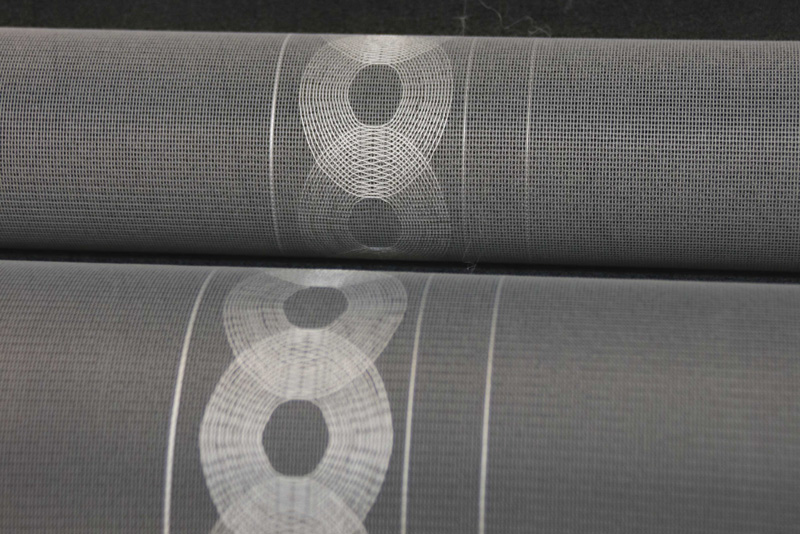

The innovative textile machinery manufacturer KARL MAYER is contributing its expertise in the field of wearables to the project work. The TEXTILE CIRCUIT team of its TEXTILE MAKERSPACE has already successfully implemented various projects in this area. In addition, an MJ 52/1 S from KARL MAYER is used at V-Trion, Grabher's research company in Lustenau, for the production of electrically conductive textiles.

DiMo-NEXT will be launched on April 1, 2024, shortly before Techtextil 2024 in Frankfurt am Main. KARL MAYER will present its contribution to the project work at the leading international trade fair for the sector.

Interacting instead of just analyzing

Ever smaller, cheaper and more precise sensors are already leading to new products and services, but these are only suitable for recording and analyzing data, for example on the length, frequency and speed of activities. DiMo-NEXT goes one step further: integrated motion sensors and psychophysiological sensors are to be combined with new, intuitive interaction concepts to support consumers in their physical activities and ensure greater motivation, performance and well-being. This approach is based on expanding the performance potential of clothing.

"For us as textile product developers, DiMo's objective means that we have to deal with the implementation of next-generation wearables," says Franziska Guth, Product Developer for Textile Technology at KARL MAYER.

The processing of electronics in textiles to record vital data has already been successful and proven. Now it is important to use the clothing to interact with the wearer, for example to optimize movement sequences and training sessions.

KARL MAYER will be demonstrating how this can be achieved at Techtextil in Frankfurt am Main from April 23 to 26. The manufacturer is looking forward to meeting its guests in Hall 12.0, Stand B73. Franziska Guth and her colleagues look forward to welcoming their visitors.