#ITMA Asia + CITME Singapore 2025

AQUARIA® © 2025 Biancalani

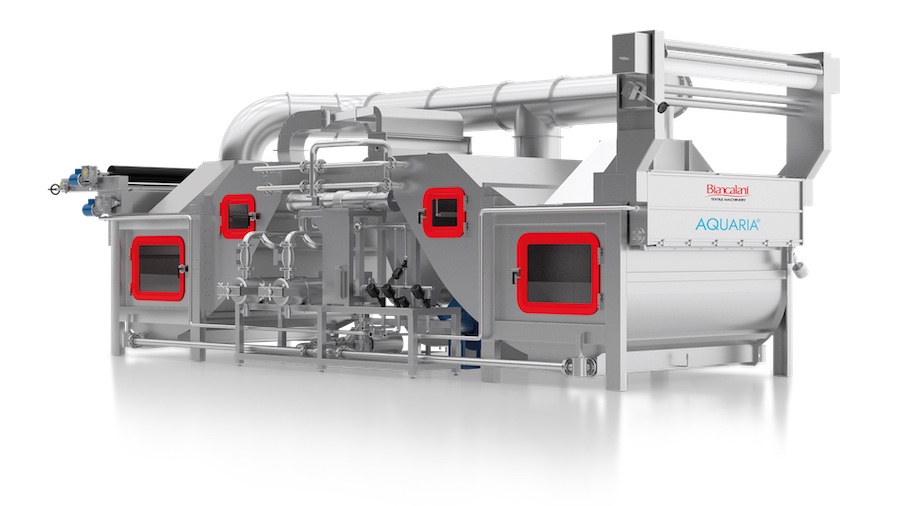

Biancalani presents AQUARIA® advanced water management drive system

Smart air-powered washing

Unlike conventional washing, AQUARIA® transports fabric using air and controlled cavitation energy. Two large accumulation chambers connected by a pneumatic ejector create an intensive yet gentle mechanical action that ensures uniform saturation, defect-free processing, and major resource savings.

Performance highlights

+++ Water consumption starting at 500 L, as low as 2–5 L/kg

+++ Eco-bleaching with < 1 L/kg discharge

+++ No harmful chemicals in many applications

+++ Widths up to 3,600 mm, speeds up to 80 m/min

+++ Industry 5.0 control with centralized monitoring and recipe storage

Versatile and efficient

AQUARIA® handles a wide range of fabrics – from silk and cotton to denim, lyocell, and synthetics – enabling treatments such as enzymatic bio-polishing, eco-bleaching (zero caustic, zero chlorine), indigo shade reduction (AQUASTONE), and relaxed mercerization.

Its modular design allows quick changeovers for applications in apparel, home textiles, and automotive fabrics.

Combining air-driven mechanics with advanced water circulation, AQUARIA® achieves measurable savings in water, energy, and chemicals, while maintaining top quality and productivity – a decisive step toward zero-discharge textile finishing.