#ITMA Asia + CITME Singapore 2025

From Smart Control to Zero Waste: SETEX sets the pace for 2025

Every kilowatt lost as steam and every extra minute in processing reduces margin and inflates the carbon footprint. SETEX shows how to turn that into measurable gain with adaptive, self-optimizing workflows. Decisions shift to the moment the batch is running. Quality stays predictable. Evidence is created as you work.

Active Energy Management

OrgaTEX captures electricity, steam and water per batch and steers usage in real time. Energy Cockpit records every watt, litre, and bar. Live Resource Analysis predicts the next peak energy demand, Plant Navigator reduces the peak before it arrives. The result: lower kWh and water per lot, proof for CO2 goals and the Digital Product Passport requirements. These mechanisms are embedded in OrgaTEX MES logic, turning energy from a static KPI into a self-adjusting feedback cycle.

SmartRecipe for predictive quality that preserves know-how

Predictive quality that keeps know-how in the company. Instead of maintaining dozens of near-duplicate recipes for each shade, load size, machine, or fiber blend, SmartRecipe uses one self-adapting process per dye class. Formula Wizard applies expert rules so liquor volumes, ramps and holds adjust to article, dyestuffs and machine limits. Target shade is reached with fewer corrections, processing time drops. Operator changes do not restart the learning curve.

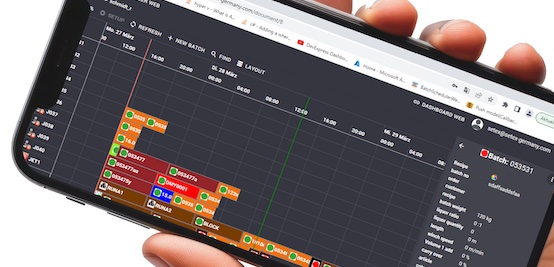

Connectivity and clean KPIs

With enhanced OPC UA, OrgaTEX X3 sends planned production orders, released recipes and adjusted parameters straight to C390 controller for machine loading. In real time, the controller returns stop reasons (including unplanned), alarms and batch consumption to OrgaTEX. Result: no OEM-specific coding, faster changeovers, fewer manual entries, and consistent, verifiable records for brands and labels such as Higg FEM, ZDHC, bluesign, OEKO-TEX STeP or ISO 14001, plus CO2 and resource evidence you can share with customers.

Within the Textile Solutions Group (TSG)

As a founding member of the Textile Solutions Group, SETEX extends the same data backbone into ERP, CAD, inspection and routing, so a mill that starts with one smart controller can grow, step by step, into a fully connected value chain.

Built in Germany. Deployed worldwide.

Visitors can meet SETEX in Singapore at Hall H7 A204 (German Pavilion). The company invites guests to bring their current bottlenecks, and SETEX will map out a path to measurable improvement.