#ITMA 2023

LAIP, dyeing technology consistency with environmental and market needs

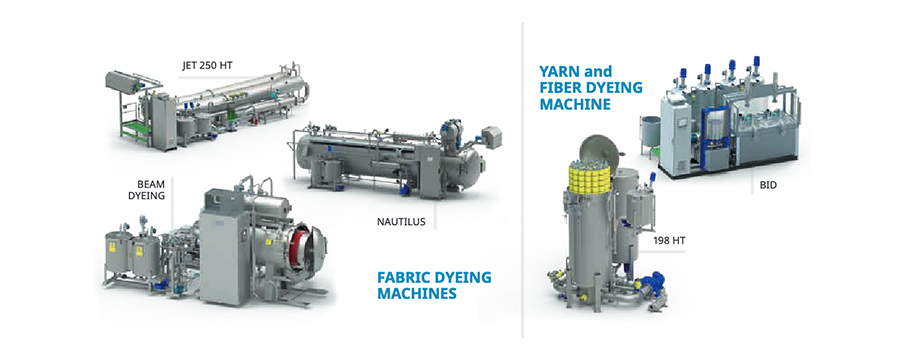

Among them:

198 HT, the highly demanded machine for tow – packages and fibre dyeing, it allows the same liquor ratio to be maintained even with partial loads!

BID, (Bobbins Injection Dyeing) ensures absolute repeatability, productivity and reliability for multicolour printing and dyeing of yarn in bobbins.

Nautilus, the cutting-edge machine. Conceived with a double belt, it is suitable for dyeing delicate fabrics keeping the low liquor ratio constant by the maximum fabric load up to 40%.

The low water consumption means low electrical consumption and energy saving.

Jet 250 HT, the easy machine that never stops to get perfectly dyed fabrics with no abrasions nor creases.

Beam, the ideal machine to dye high end silk and technical fabrics, tubular and warp knit for sportwear enabling the optimisation of production times and superlative technical performance.

The company is driven to always face new challenges and the interaction with customers stimulate the design and technology department to find suitable solutions to face the new and important needs of dyehouses. From this ability to dialogue, the innovations - that will then be globally disseminated - are born.

It is not easy in the world of dyeing to find eco-friendly solutions, as requested by many customers. Yet they must be faced and resolved. This is where innovation comes from:

super-efficient pumps, low liquor ratio, ease of use, automated systems, efficiency improvement and industry 4.0 features. All aimed at creating ever more performing dyeing machines in terms of sustainability that goes towards an ecological transition that sees LAIP and its customers seriously committed.

LAIP stand: HALL 11 • BOOTH C105