ITMA-Asia + CITME-2014

Schlafhorst at ITMA Asia + CITME in Shanghai

As the market and technological leader, Schlafhorst answers the questions that demanding customers are now posing in the staple fibre spinning field. How can textile companies increase their productivity and efficiency further? How are rival companies developing? What are the groundbreaking technologies for the markets of the future? Schlafhorst points the way and opens up new perspectives for the industry with pioneering innovations and intelligent automation solutions.

The company from Übach-Palenberg in Germany with its long tradition is dedicated to ensuring the success of its customers. It has a presence in textile markets across the globe with an extensive sales and service network, along with production plants and technology centres in China and India. René Bucken, Schlafhorst's marketing manager, is counting the days to the start of the exhibition. "We are looking forward to presenting our new products in Shanghai and discussing our response to the pressing issues in the industry with people for whom, like us, textiles are in the blood."

Rotor spinning machines from Schlafhorst

Schlafhorst comes in the role of a pacesetter for the industry. Whether Autocoro or BD, rotor spinning machines from Schlafhorst are in a class of their own.

The company's flagship, the Autocoro 8, can now demonstrate its true profitability on 552 spinning positions. With rotor speeds of 160,000 rpm tested in practice and new automation solutions, the Autocoro 8 is responsible for a sensational jump in productivity. The new semi-automatic BD 6 rotor spinning machine has been equipped with patented digital technology from the high-end world of the Autocoro. It is highly productive and delivers packages that are scarcely distinguishable from Autocoro packages.

Autocoro 8: unchained productivity

For years, the 150,000 rpm sound barrier was regarded as insurmountable in terms of rotor speeds. The Autocoro 8 has smashed it. More and more spinning mills are now producing high-speed yarns constantly at 160,000 rpm. Reports of sensational boosts in productivity are making the industry sit up and listen. With a new maximum machine length of 552 spinning positions, the Autocoro 8 is 15% more productive. But this unchained productivity doesn't take up any more space, because the Autocoro 8 with its single-drive technology is still 13% more compact than belt-driven machines of comparable length from other manufacturers. New, intelligent automation solutions ensure even greater productivity, permitting a seamless lot change on single-lot machines among other things. At the same time, batches can be reliably separated if needed without all spinning positions having to run out first when spinning cans or components need replacing. In other words, changing material no longer kills productivity.

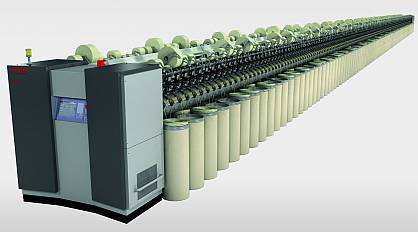

The new BD 6: packages with the Autocoro character

In the world of semi-automatic machines, the new BD 6 is in a class of its own. Even with the basic specification it produces packages with the Autocoro character. The patented digital piecing technology DigiPiecing with its high level of piecing reliability and the highly precise winding technology from the Autocoro are capable of even more. On its 480 spindles the BD 6 achieves a take-up speed of 230 m/min. This is 40% faster and more productive than its predecessor. Countless improvements have simplified operation so that staff can maintain a high efficiency rating more easily. A broad spectrum of expansions also opens up new business horizons for semi-automated spinning mills. The new BD 6: new generation. More profit.

Pic:The new BD 6 – in a class of its own in the world of semi-automatic machines

Zinser ring spinning machines

"A benchmark for productivity and efficiency"

Schlafhorst demonstrates afresh that Zinser ring and compact spinning machines are the undisputed benchmark for productivity and efficiency. Automation, a longstanding issue The subject of automating processes in the spinning mill has been an issue for some time. Since it is hard to find suitably qualified staff to work in ring spinning mills, it is a topic that is becoming more urgent, regardless of staff costs and the demands of the market. Many working processes can be simplified and designed to be less labour-intensive thanks to automation. Automation also improves quality, as manual intervention can damage the material and impair the quality. Schlafhorst offers economical automation solutions in all areas. With full automation of the ring spinning mill, no further manual handling is required from the roving frame to the package winder.

Doffing automatically with the CoWeMat

An effective tool in reducing the labour requirement in the ring spinning mill is automatic doffing. Using the most effective, reliable doffer in the world, the CoWeMat from Zinser, up to 61% of labour costs can be saved depending on the yarn count and bobbin format. At the same time, the CoWeMat reduces the staffintensive logistics outlay in the mill. The interruption-resistant, unsorted tube feed CoWeFeed guarantees frictionless processes that eliminate the need for operator intervention and reduce operator input by 66%. The fully automated link to the winding machine, in which the spinning and winding capacity can be suitably coordinated, offers even greater benefits than this standalone solution. This increases the efficiency rating of the overall installation thanks to optimum utilisation.

ZinserRing 72 and ZinserImpact 72, a new machine generation

The new ZinserImpact 72 compact spinning machine will be on display in combination with the Autoconer X5 at Schlafhorst's exhibition booth in Shanghai. The new ZinserImpact 72 is equipped with the world's most efficient self-cleaning compact spinning technology, Impact FX. This new machine generation of the ZinserRing 72 and ZinserImpact 72 with its proven top-notch technology and various automation options offers the maximum productivity, quality and profitability. Zinser thus sets new standards when it comes to benchmarking efficiency and utility value in the ring spinning mill.

Autoconer X5 with intelligent material flow technology

In Shanghai, Schlafhorst presents the Autoconer X5 linked to the new compact spinning machine ZinserImpact 72. The trend towards automation of the ring spinning mill continues unabated. Following Indonesia, Thailand and Korea, a real wave of automation is now engulfing China and India in Asia. Rising labour costs and more sophisticated quality requirements as well as a growing shortage of suitable staff are prompting more and more spinning mill managers to choose innovative automation solutions from Schlafhorst when making investment decisions. They are investing in large linked installations and also standalone machines like the Autoconer X5 type D, which makes it particularly easy to automate manual process sequences.

FlowShare FX for greater reliability and productivity

The automation highlight on the Autoconer X5 being exhibited is FlowShare FX. Schlafhorst has once again fundamentally improved the logistical intelligence and process reliability of the Autoconer with what is currently the most modern, smartest material flow technology. FlowShare FX is the only system on the market to balance out fluctuations in the material supply entirely independently and reliably: Vario Reserve adjusts the number of reserve bobbins to match the requirement, High-Speed Feeding uses a differentiated belt speed to ensure a supply to meet this requirement and Intelligent Bobbin Sharing exchanges bobbins between the winding positions entirely autonomously if a material bottleneck threatens. This added intelligence in the material flow increases the reliability, productivity and efficiency of the spinning and winding process.

FX technology on the Autoconer

The machine at the exhibition booth is also equipped with the top features of Schlafhorst's winding and splicing technology. PreciFX, Autotense FX, Ecopack FX, Speedster FX and the injection splicer guarantee a unique package quality while maintaining a high level of productivity. PreciFX has established itself as a pioneering innovation globally in the market and impressively demonstrated its performance in practice. The simple, flexible handling of PreciFX and package designs that are optimally adapted to the requirements of downstream process stages convince its users in all application areas. Thanks to PreciFX, the compromises that have had to be made over the years regarding the structure of hard and dye packages as well as in bobbin processing and rewinding have finally been consigned to the past.

Schlafhorst Customer Support

"A secure innovation path to the future"

Companies that purchase textile machines from Schlafhorst secure an economical innovation path to the future. The German textile machinery manufacturer implements technological innovations so that they can be retrofitted to existing machines. With its original parts, modernisation kits, technology kits and service kits, Schlafhorst assumes responsibility for innovation throughout the product life cycle and ensures that even customers with older machine generations always benefit from technological advances.

Over 450 service staff in 20 service and three technology centres advise customers all over the world with regard to productivity and quality increases. They support customers with regard to investment decisions and produce detailed efficiency calculations. New purchase or modernisation? When will the company achieve the better return on investment in the current market conditions? The Schlafhorst Service Team supports this central business decision with its unique expertise in the textile sector.

Thanks to Schlafhorst's customer-oriented innovation philosophy, the modernisation of existing installations is the best economic decision in many cases. Schlafhorst customers are not only buying a machine, they are also benefiting from a life-cycle partnership, which guarantees them a continuous strengthening of innovation in the ongoing production operation. Schlafhorst implements this life-cycle partnership among other things with tailor-made modernisation and technology kits. Improvements in the design of individual parts and spinning components or entire assemblies can thus be retrofitted quickly and easily.

Retrofit additional spinning positions and compact technology as required

At ITMA ASIA 2014, Schlafhorst presents two interesting retrofit packages among others. With the Autocoro Modernisation Kit for machine extension, the Autocoro 8 can be extended to 552 spinning positions, thereby increasing the productivity per machine by around 15%. The Zinser Modernisation Kit for compact spinning technology integrates the world's most efficient compact spinning technology into Zinser ring spinning machines of the 350, 351, 450 and 451 series.

Schlafhorst's claim to innovation also extends to the original parts. These are continuously improved and form part of the technology company's innovation pipeline. Schlafhorst measures the quality of its innovations against the customer's success. Over 5,700 active customers in more than 120 countries are already benefiting from the innovative technology and unique customer support offered by Schlafhorst.

Pic: Schlafhorst names their customer support a secure innovation path to the future