#INDEX 23

INDEX 23: Reifenhäuser Reicofil presents new RF5 XHL technology for super soft and perfectly drapeable nonwovens

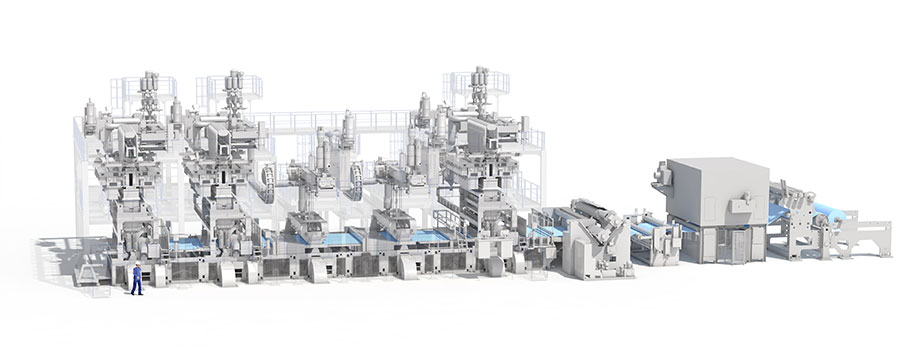

The suffix XHL stands for Extra High Loft. RF5 XHL is the evolution of the proven RF5 technology, targeted at super soft and drapeable nonwovens for the hygiene industry. "Thanks to highly crimped fibers with reduced fiber size, our XHL nonwovens offer a new level of quality with super soft touch for nonwoven products made from them – such as top sheet and back sheet," explains Markus Müller, Vice President Sales & Marketing of the Reifenhäuser Group. "At the same time, we achieve a huge improvement in the carbon footprint of up to 30 percent thanks to reduced resource use."

The RF5 XHL technology relies on the specially patented BiCo process. This combines two different raw materials in one fiber in the spunbond process, creating a bimetallic effect and optimally crimping the fiber. This results in a weight reduction of up to 25 percent for fiber sizes at 1.0 denier. At the same time, thickness increases by up to 30 percent compared to state-of- the-art material.

The new RF5 XHL lines are also equipped with particularly energy-efficient components, enabling resource-saving nonwoven production at high line speeds. To reduce production waste to a minimum, all raw materials are made of polypropylene (PP), for simple and efficient inline recycling. In contrast, common mixed-material fabrics made of PP/PE or PET/PE are very difficult to recycle. In addition, to meet the ongoing demand for more sustainable nonwoven products, RF5 lines also process bio-based raw materials on request.

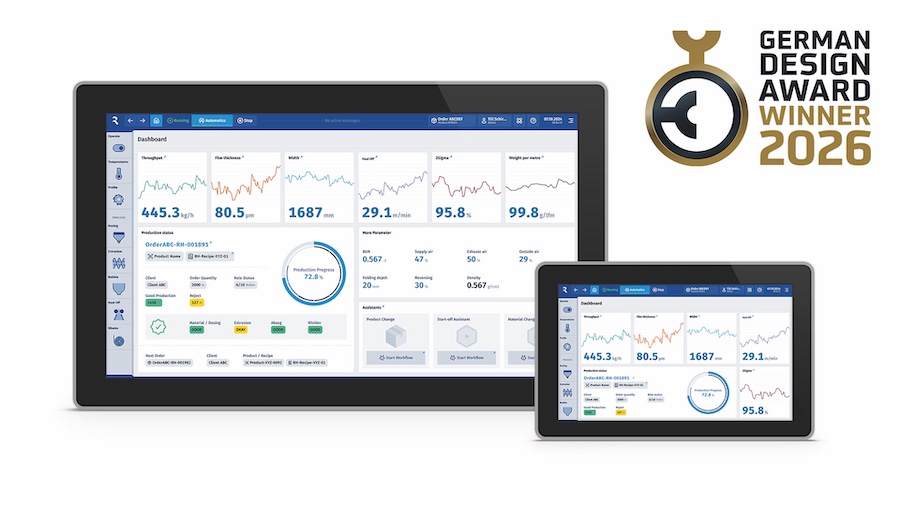

Smart digitalization increases production efficiency

With c.Hub, the new data connection platform of the Reifenhäuser Group, Reicofil offers its customers a digitalization solution that is consistently tailored to the requirements of nonwovens production. Customers have the possibility to securely network the data of their Reicofil lines, peripherals as well as ERP and MES systems via the c.Hub middleware, to store it centrally for easy analysis. Line operators can thus monitor and document their production and increase production efficiency based on data. Coming with various software bundles, c.Hub is offered as an on-premise solution, i.e. it can be operated locally and remains under the full data sovereignty of the user.