#Dyeing, Drying, Finishing

Graniteville Specialty Fabrics takes huge leap with digital finishing

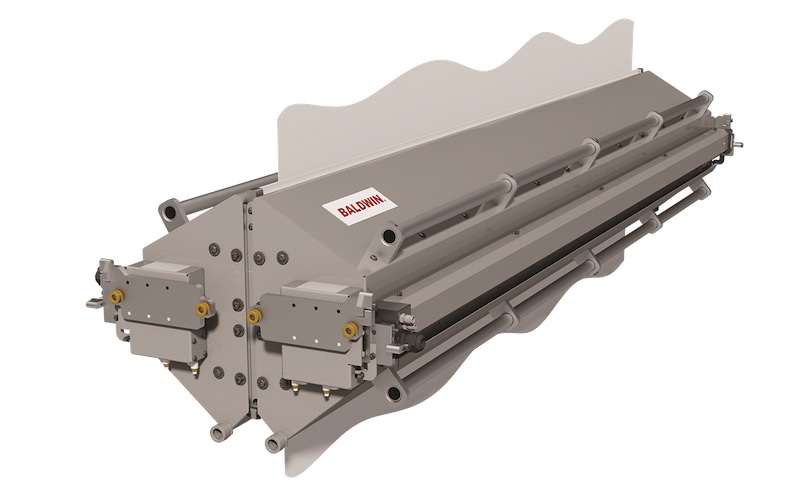

Based in Graniteville, South Carolina, Graniteville Specialty Fabrics produces coatings and coated fabrics that are resistant to water, fire, UV and weather for the military, marine and tent markets. The installation of Baldwin’s TexCoat™ G4 is part of a major facility upgrade to maximize production efficiency and capacity in the durable water-repellent finishing and coating line to meet growing customer demand for advanced engineered products.

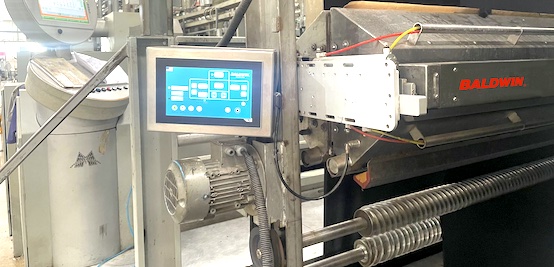

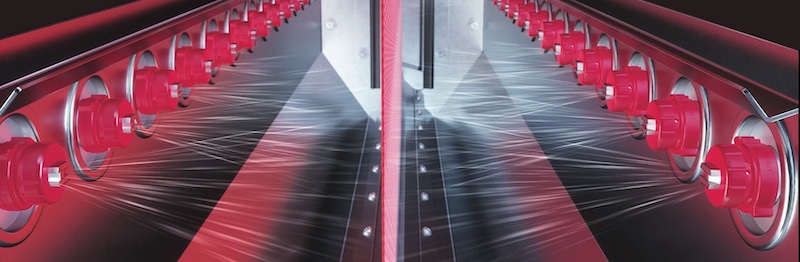

With extensive sustainability benefits, unprecedented tracking and process control, and Industry 4.0 integration, the TexCoat™ G4 consistently provides high-quality fabric finishing, with no chemistry waste, as well as minimal water and energy consumption. This system utilizes non-contact precision-spray technology, ensuring precise finishing coverage with the exact amount of chemistry for reaching the optimal performance of the fabric. Changeovers (pad bath emptying, cleaning and refilling) are significantly reduced, resulting in substantial chemical conservation and increased productivity.

“We were pleased to be a key partner in Graniteville Specialty Fabrics’ modernization project,” said Rick Stanford, Baldwin’s Vice President of Global Business Development, Textiles. “The team reached out to us, and it was clear that the TexCoat™ G4 was the right tool to help them minimize waste and increase productivity.”

Doug Johnson, Graniteville Specialty Fabrics’ Executive Vice President of Development and Technical Services, said the company needed to increase its productivity and sustainability, without sacrificing fabric quality and performance.

“Anytime you change from a traditional process like padding, it is human nature to be a little skeptical,” said Johnson. “Baldwin organized production-scale trials for us at a nearby TexCoat™-equipped factory. We took the finished fabric and scrutinized the look and feel, and performed a battery of tests in our lab to American Association of Textile Chemists and Colorists spray-rating and hydrostatic-head standards. The results were impressive. Moreover, when we commissioned our TexCoat™, we duplicated and exceeded the fabric performance realized during the trials.”

“[TexCoat™] allows us to have full control over where we spray the chemicals, and allows us to save money in the process” states James McKenzie, Graniteville Maintenance and Facilities Manager. “With the machine in production, it is a rocketship compared to a rock.”