#ITMA Asia + CITME 2022

“Start with Baldwin and finish with perfection”

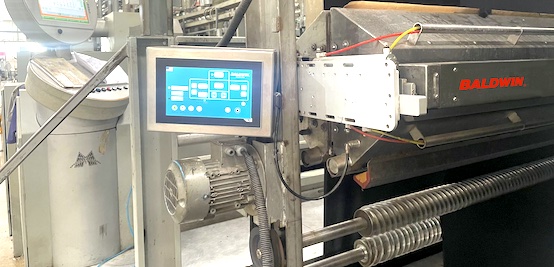

ITMA Asia participants can stop by and “touch” Baldwin’s wide array of TexCoat G4-applied fabric samples from textile mills around the world and experience what precision finishing “feels” like while learning how the technology eliminates chemistry waste on changeover, saves water, and achieves faster speeds through the stenter frame and relaxed dryer.

ITMA Asia 2023 Attendees to Discover Faster and More Sustainable Textile Finishing with Precision Spray TexCoat™ SystemBaldwin’s team will be available to discuss how the company’s technology can meet the textile supply chain’s sustainability and carbon footprint goals while improving performance and saving money. In the context of a cost-sensitive global economy and an increased focus by brands, consumers and regulatory agencies on sustainability, customers are placing a premium on sustainability-advantage textile production.

“We saw enormous interest at ITMA 2023 in Milan–with more global textile finishers excited to put TexCoat to work,” said Rick Stanford, Baldwin’s VP Global Business Development, Textiles. “They can expect increased profitability, lower energy use, and reduced carbon footprint in addition to exercising precision control with our patented precision spray technology.”

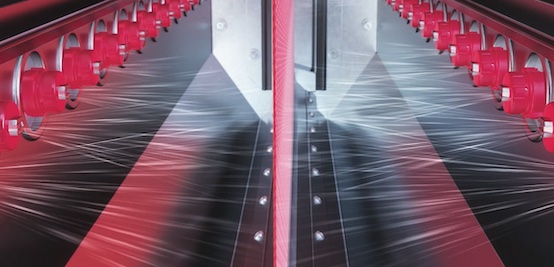

TexCoat G4’s non-contact spray technology offers numerous advantages compared to outdated finishing-chemistry application methods. TexCoat G4 processes a wide range of low-viscosity water-based chemicals, such as durable water-repellents – including PFAS-free, softeners, anti-microbials, easy-care and flame retardants. The company's technology uses the same chemicals as found in traditional pad baths with no special auxiliaries required.

Testimonial videos from Pincroft Dyeing and Print Works and Graniteville Specialty Fabrics along with a video highlighting Baldwin’s partnership with North Carolina State University will also be screened at Stand H5C22.