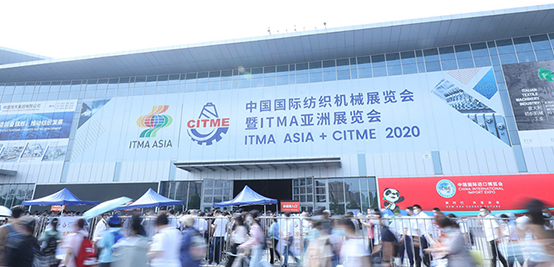

#ITMA Asia + CITME 2022

Oerlikon Barmag and Nanshan Fashion signed a contract on the Strategic Cooperation Agreement for PA6 and PA 6.6 solutions

At the first day of ITMA ASIA + CITME 2022 in Shanghai, China

“For Oerlikon, it is the first time we have had the opportunity to work with an integrated textile manufacturer representing a well-known brand, DELLMA. This should help us to better understand the ongoing developments in the consumer market and the demands that these market developments place on the manmade fiber industry, said Georg Stausberg, CEO Oerlikon Polymer Processing Solution at the first day of the show.

“It is the first time for Nanshan Fashion to enter the field of manmade fiber production. We at Oerlikon Barmag are pleased and proud that Nanshan Fashion has chosen our company as partner for this step. We are the market leader for many technologies in the field of chemical fiber production and we will support Nanshan Fashion with all our experience in establishing a new branch of your business,” said Stausberg.

“I am convinced that both parties are strongly committed to building Nanshan Fashion's nylon business into a benchmark in the nylon industry and moving towards brand internationalization. This cooperation is a milestone for both parties,” said Zhao Liang, Chairman and General Manager of Shandong Nanshan Fashion.

China National Textile and Apparel Council (CNTAC) President Sun Ruizhe also joint the signing ceremony at Oerlikons booth in hall 7.1, A55. He said: “Congratulation to both companies. We can see a bright future for this cooperation. Within the China textile industry, we need further international partnerships like Oerlikon Barmag and Nanshan Fashion.”

As a leader in the manmade fiber equipment industry, Oerlikon Barmag has always been known for its high-speed, efficient, energy-saving, and stable yarn quality, as well as its complete supporting equipment and services, providing solutions that cover the entire textile value chain. Over the years, Oerlikon Barmag and several leading companies in the manmade fiber industry have jointly completed several large-scale projects from melt to yarn, laying a solid foundation for the development of China's textile industry. In recent years, Oerlikon Barmag has focused on innovation, continuously optimizing the spinning design, updating the WINGS family, and developing the EVO DTY machines. In addition, Oerlikon Barmag is increasingly focusing on sustainable production. Since the introduction of the e-save label for all products in 2004, Oerlikon Barmag has continued to move towards greater eco-friendliness and efficiency.

The cooperation with Nanshan Fashion is Oerlikon Barmag's first project to provide a complete solution for nylon filament. The scope of supply includes a complete set of equipment from chip drying, spinning, winding to texturing. The achievement of an integrated quality control from chip to yarn is of great significance.

According to the “Strategic Cooperation Agreement,” both parties will engage in equal, win-win and complementary cooperation based on mutual trust and long-term development considerations. Target will focus on high-end nylon production by implementing the concept of green production and pursuing excellence and innovation in PA processes. Among them, Oerlikon Barmag will provide high-quality and high-performance differentiated nylon filament production solutions, integrate the advantages of Nanshan Fashion's scientific and technological R&D resources, and jointly promote the global leading position of "Oerlikon Barmag & Nanshan Fashion" joint brand in the nylon filament industry.