#Denim

SAITEX releases 2023 Impact Report: Shaping the future of sustainable denim

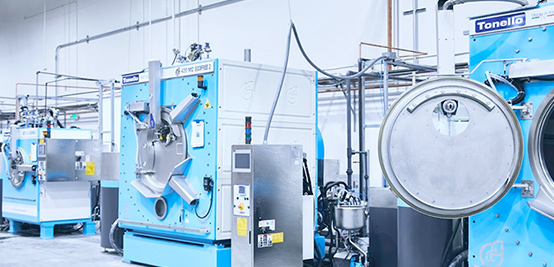

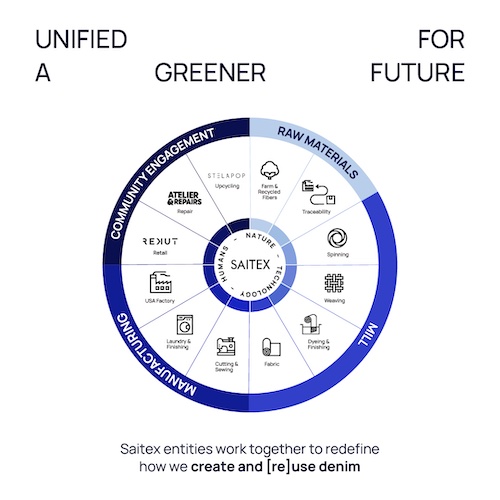

Founded in 2001, SAITEX has been at the forefront of clean denim production, earning accolades like "The World’s Cleanest Denim Factory" from Bloomberg. Over the years, it has evolved into a vertically integrated ecosystem that encompasses multiple initiatives. These include its sustainable denim production facility in Vietnam (2006), a trend-responsive Los Angeles facility (2021), the SAITEX Mill for clean fabric spinning (2022), the upcycling division STELAPOP (2019), the workforce inclusion program REKUT (2019), and the denim repurposing project Atelier & Repairs (2021). Together, these entities work towards a unified vision of redefining how denim is produced and reimagined.

The 2023 Impact Report underscores SAITEX’s emphasis on circular manufacturing, integrating waste-to-product transformations with regenerative practices. Innovations such as Smart-Indigo™ technology, AI, IoT, and robotics enable efficiency, sustainability, and traceability, making SAITEX a model of Industry 4.0 advancements. CEO Sanjeev Bahl emphasizes the importance of transparency in driving progress, stating, "Sharing our impact—whether positive or negative—is essential for improvement. Our evolution as a circular system depends on setting ambitious goals and continuously improving."

The company’s collaboration with renowned global brands like G-Star, Everlane, Zara, and IKEA further illustrates its ability to produce high-quality denim responsibly while maintaining stringent adherence to sustainability certifications, including bluesign®, GOTS, and Cradle to Cradle.

Key achievements from the report include:

+ Cradle to Cradle Certified® Gold Denim: By 2023, 25% of fabrics produced at the SAITEX Mill in Vietnam met this standard, significantly reducing CO2 emissions, energy usage, and water consumption.

+ Smart-Indigo™ Technology: Since 2021, the facility has reduced CO2 emissions by 90%, energy use by 70%, and water consumption by 30%, demonstrating the transformative power of innovative dyeing technologies.

+ Inclusive Workforce: Through the REKUT program, 98% of employees from marginalized backgrounds were integrated into garment production, reflecting the company’s dedication to equity and social empowerment.

SAITEX’s approach combines advanced technology with human creativity to reshape denim manufacturing while addressing environmental and social challenges. The report not only highlights its progress but also sets the stage for future initiatives aimed at further embedding circularity into its processes.