#Composites

DORNIER at JEC World 2023: Machines and lines for modern composites production designed to improve sustainability

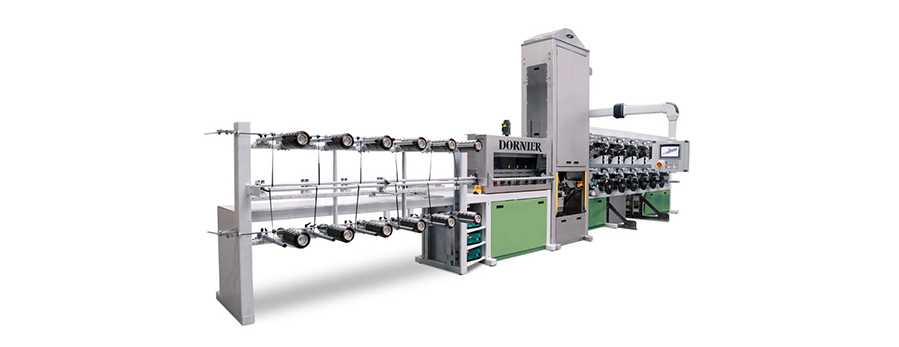

What a modern and economical production from tape to organo sheet looks like is demonstrated by the machine and plant manufacturer DORNIER with its production line PROTOS® (Polymer and Roving To Sheet). PROTOS® plants produce thermoplastic fiber composites based on unidirectional continuous fiber reinforcements (UD tapes) and organo sheets with high drapability and quality. The Tape production plant and Tape weaving machine of the PROTOS® line permit to easily produce light-weight components specifically on demand – featuring any desired geometry, individual Tape width and thickness, the right blend of fibers and matrix as well as individual mechanical properties. „There is a big difference between ready-made sheets bought and transformed or sheets produced on PROTOS® in terms of flexibility and costs“, says Mr. Josef Klingele, head of DORNIER’s Composite Systems production line.

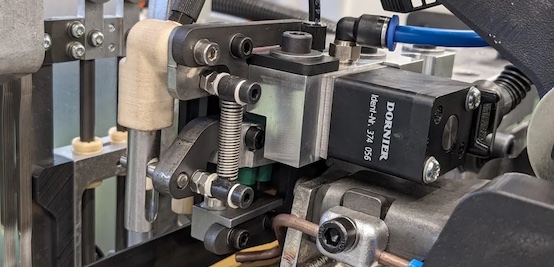

Benchmark for high performance fabrics: P2 Roving rapier weaving machine?Since the P2 roving rapier weaving machine has been introduced at the last JEC as the successor to the P1, it has enjoyed great popularity among manufacturers of high-quality reinforcement fabrics. The significantly improved P2 is viewed, like the P1 before it, as global benchmark for the production of high-performance fabrics made of carbon, glass and aramid fibers. Its higher structural rigidity, improved insertion rate, the patented, maintenance-free DORNIER SynchroDrive® and the optimized positive center transfer makes the P2 the most versatile rapier weaving machine in the world. Further strongpoints of the P2: its waste saving device is considerably reduces filling waste and its enhanced shed geometry ensures symmetrical warp end paths, both features taking production of carbon fabrics for high-end applications to an even higher level.

From heavy tow to special fabric: Rapier weaving machine P2 Mono?The new features of the one-arm rapier weaving machine P2 Mono from DORNIER will also be a topic in Paris. This highly flexible machinery platform is available in various versions. Manufacturers of fiber composite components process special fiber materials on the P2 Mono into high performance reinforcement structures. In combination with DORNIER’s Zero Twist Feeder the P2 Mono ZT is able to insert two filling colors twist-free at high speed and with an extended pattern variety.

Production technology for complex fiber structures: the TRITOS® line?The production system TRITOS® (Textile Roving into Three-dimensionally Oriented Structure) shows that high-quality 3D fabrics can be produced with very good damage tolerance and high dynamic load capacity in industrial manufacturing areas with high cost pressure. 3D fabrics can be realized with thicknesses of up to 100 mm for use in high-performance applications. „We are looking forward to meeting our customer personally at the JEC after the years of Corona related restrictions“, says Ms. Britta Sköck-Hartmann, product manager of DORNIER Composite Systems.