#Composites

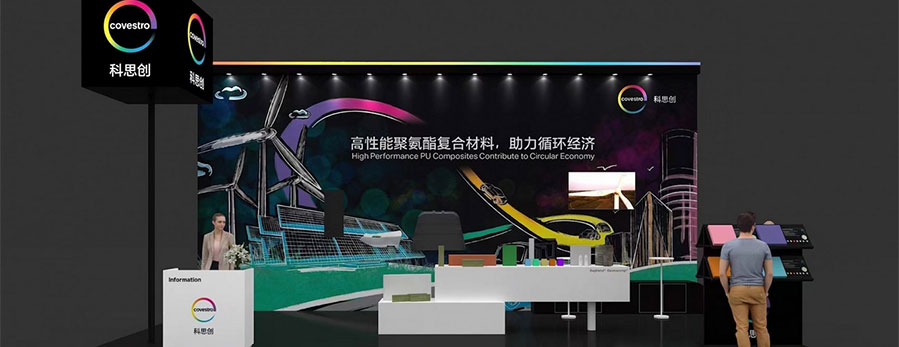

Covestro drives circular economy forward with high-performance PU composites

Covestro will showcase various PU composite solutions at the 2023 China Composites EXPO Shenzhen, held from March 23-25 at Booth 1201 in Hall 2 at the Shenzhen Convention and Exhibition Center. These solutions, created in partnership with other companies, include pultruded profiles for windows and solar frames, rotor blade sections for wind turbines, top covers for new energy vehicle (NEV) battery packs, power distribution poles, and facade brackets. These products are made using a range of composite processes such as PU pultrusion, high-pressure resin transfer molding (HP-RTM), infusion, and filament winding.

Baydur® Pultrusion window frame

The Baydur® Pultrusion window frame is designed to reduce the energy consumption of buildings by providing exceptional heat insulation and mechanical properties. These frames are made of fiberglass reinforced polyurethane composites, with a waterborne polyurethane coating on the surface. Compared to conventional aluminum alloy or PVC windows, these composites have a smaller environmental impact and lower carbon emissions due to their superior insulation performance.

Baydur® Pultrusion solar module frame

The Baydur® Pultrusion solar module frame is a non-metal solution that combines a PU pultrusion composite with a PU waterborne coating. It has excellent mechanical properties and can resist strong chemical erosion, making it ideal for high humidity and high salt fog areas. Unlike aluminum alloy frames, Baydur® frames don’t require grounding, and can improve energy generation efficiency of solar panels. It is a cost-effective solution for solar parks and Building Integrated Photovoltaic applications.

Baydur® HP-RTM top cover for NEV battery packs

The Baydur® HP-RTM top cover for NEV battery packs is a key application of PU in new energy vehicles. It is lightweight and can be as thin as 0.8mm, thus reducing total carbon emissions. The cover is also flame-retardant to ensure safe protection for vehicle batteries. Additionally, the HP-RTM process significantly improves manufacturing efficiency and reduces operational costs with its “one-drives-two” design, enabling one injection machine to service two press machines simultaneously.

Power distribution poles and telecommunication towers

Power distribution poles and telecommunication towers using Baydur® and Desmocomp® were developed to meet the needs of vast areas, regardless of the environment or terrain. These solutions are only one-eighth the weight of conventional concrete poles, generating substantially fewer CO2 emissions during manufacturing and transport processes. They can also be effectively transported and installed even in difficult terrains. Furthermore, their inherent structural differences make them more resilient in extreme conditions such as typhoons, lightning storms, and corrosive environments, providing a stable lifespan of over 40 years with significantly lower maintenance costs over time.

Covestro also offers low-carbon versions of these polyurethane solutions containing alternative raw materials, such as mass-balanced polyurethanes certified by ISCC PLUS and partial bio-based products, to help customers along the value chain transition to a circular economy.