#Chemical industry

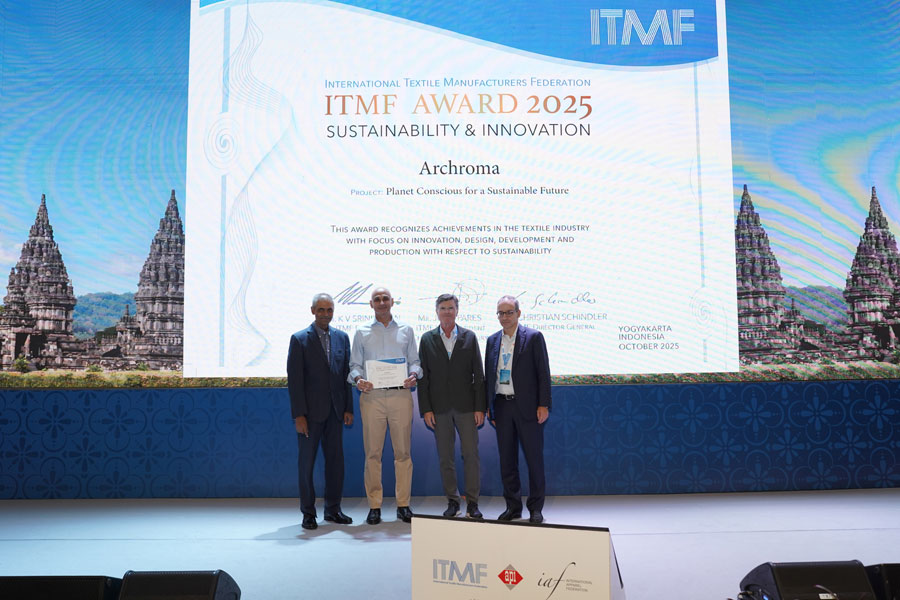

Archroma wins 2025 ITMF Sustainability & Innovation Award for distressed denim breakthrough

“Archroma believes in challenging the status quo. Under our planet conscious roadmap, we seek solutions that not only advance sustainability but also nurture the creativity and profitability of textile manufacturers,” Dhirendra Gautam, Vice President Commercial, Archroma said. “DENIM HALO exemplifies this approach, and we’re honored that it has been recognized by ITMF. In partnership with mills across the globe, we’re proving that world-class sustainability and world-class products aren’t trade-offs – they’re the same goal.”

A consumer favorite for decades, distressed denim is more popular than ever. But achieving the coveted worn and faded look remains problematic, involving manual scraping, hazardous potassium permanganate sprays or energy-intensive stone-washing. Traditional indigo and sulfur dyeing processes add to the burden, with high water and energy consumption and significant effluent discharge.

DENIM HALO is a breakthrough alternative. It draws on a unique new chemistry, DIRSOL® RD, and a broad portfolio of textile dyes based on decades of advanced research to produce laser-friendly denim with outstanding contrast on intense black and indigo shades.

DIRSOL® RD p is a new viscosity-modifying and patented pretreatment that enables superficial dyeing while also reducing water, energy, and greenhouse gas emissions in processing and wash-off. In DENIM HALO, it is combined with a tailored Archroma dye solution according to mill-specific production needs:

- DENISOL® pre-reduced indigo dyes, including an innovative aniline-free formulation;

- DIRESUL® pre-reduced sulfur dyes, including an energy-saving black formulation; and

- EarthColors®, biosynthetic earth-tone dyes made from agricultural waste.

Impact assessments using Archroma's ONE WAY Impact Calculator demonstrate substantial environmental benefits for DENIM HALO versus standard processes with ZDHC Level 3 MRSL compliance. Results include water savings of 40-56%, energy reductions of 30-36%, and CO2 emission cuts of 33-34% depending on the dye formulation used. [See infographic: DENIM HALO Environmental Impact Results]

The benefits extend beyond sustainability to safety, and economics. Mills can produce distressed effects without modifying standard dye recipes or equipment setup. The process enhances worker safety by enabling high-contrast laser etching, eliminating potassium permanganate and manual scraping. DENIM HALO also reduces caustic soda consumption in sulfur mercerizing and enables easier washdown. Technical advantages include reduced yarn shrinkage and improved garment tensile strength, especially on black denim, with lower chemical use in dyeing and finishing.

The ITMF Awards celebrate achievements in two categories: Sustainability & Innovation and International Cooperation. Winners were honored at the ITMF Annual Conference, held in Yogyakarta, Indonesia from October 24-25, 2025.