#Yarns

B.I.G. Yarns strengthens European market position with major investment in state-of-the-art yarn production

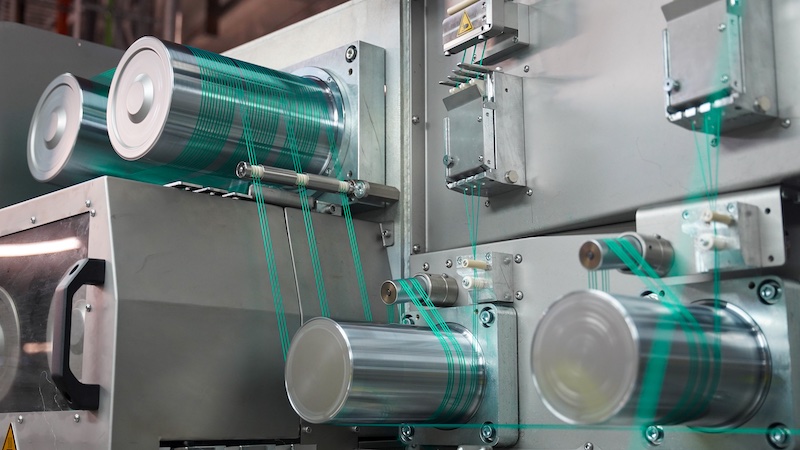

B.I.G. Yarns focuses on the development and production of 1-step 3-ply yarns using the latest technology to meet the need for flexibility and broader design possibilities in the carpet tile segment. The newly developed machine park represents a crucial step in B.I.G. Yarns’ growth strategy, ensuring a more energy-efficient, faster, and more flexible production system. By enabling smaller batch sizes and more adaptable production runs, B.I.G. Yarns will provide its contract customers with a highly competitive and sustainable product offering.

B.I.G. Yarns' advanced yarn technology increases design, contrast, and color freedom for carpet tile manufacturers while improving flexibility and service level. “At B.I.G. Yarns, we believe in the power of innovation and operation expertise to offer our customers best in class solutions,” said Emmanuel Colchen, General Manager at B.I.G. Yarns. “This investment underscores our long-term commitment to the European market and our ability to deliver superior and sustainable yarn solutions that meet the evolving needs of our customers.”

By continuing to also invest in Europe, B.I.G. Yarns is making a strong statement about its dedication to local entrenchment in a highly competitive industry. While market pressure continues to grow from manufacturers in the Middle East and Asia, B.I.G. Yarns leverages its strategic location in Europe—within 500 km of its most important customers—to ensure faster delivery, closer collaboration, and an unparalleled service level.

This bold step not only strengthens B.I.G. Yarns’ market leadership in 1-step 3-ply yarns but also highlights its vision for a more sustainable and innovative future in yarn production.