#Yarn & Fiber

Durak Tekstil restructures operations in China and begins exporting to the region from Türkiye

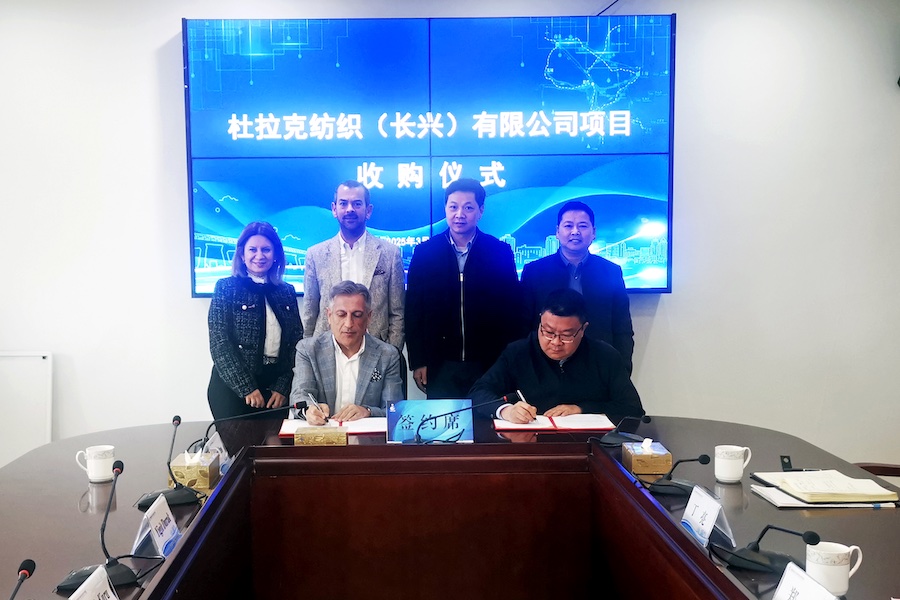

Following two years of structural transformation, the company successfully redefined its Chinese operations to focus on supply, new business development, and direct exports from Türkiye. As of early 2025, production previously handled at the Chinese facility has been relocated to Türkiye. By encouraging its Chinese and Far Eastern customers to source directly from Türkiye, Durak Tekstil has reinforced the strength and reliability of the DURAK brand. This strategic shift has allowed the company to leverage the market presence and extensive network it has built over 17 years in China to create a competitive advantage.

Key benefits of the new strategy for Durak Tekstil and TürkiyeConsistent Export Operations: Durak Tekstil now exports monthly from Türkiye to the Durak China center, maintaining uninterrupted order and shipping schedules for approximately 500 customers in China and the Far East. The company has upheld high levels of customer satisfaction through reliable stock supply over the past six months.

Cost Efficiency: Consolidating all production in Türkiye has enabled the Durak Group to achieve significant cost savings.

Transformation of the China Entity: The Durak Tekstil company in China has been restructured into a trading business. Building on its strong reputation and customer trust in the region, it has adopted a new business model, engaging in import-export trade between China, Türkiye, and other countries—including products outside its core textile operations—starting in 2025.

Increased Investment in Türkiye: With the support of Türkiye’s Ministry of Trade, Durak Tekstil transferred its machinery from China to Türkiye, increasing its domestic production capacity by 30%. By selling its real estate in China, the company reinvested in its operations, making a total direct investment of approximately USD 20 million. In addition to expanding its existing facility in Vak?fköy, Bursa, Durak Tekstil plans to establish a new factory on its land in the TOSAB industrial zone using proceeds from the sale.

This strategic realignment not only enhances Durak Tekstil’s global competitiveness but also strengthens Türkiye’s position as a hub for high-quality textile production.