#Yarn & Fiber

Upgraded Lenzing E-Branding Service offers even greater convenience to value chain users

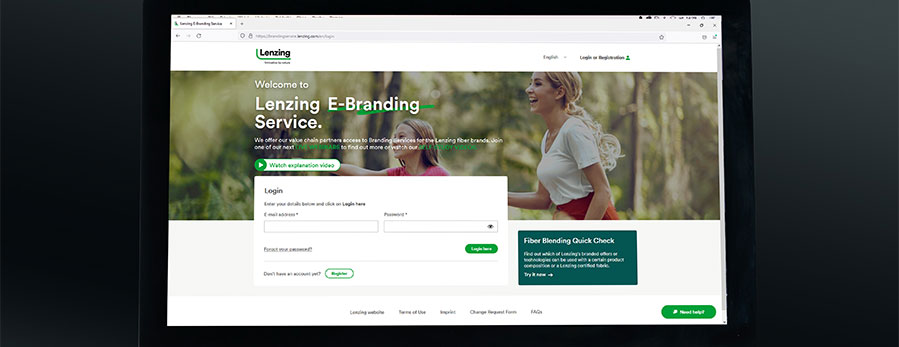

Users will be able to use the new features – Artwork Approval, Fiber Blending Quick Check Tool, Onboarding Tool, E-Branding Master Class and E-Branding Helpdesk – to enjoy a smoother experience and greater convenience, as well as enhanced transparency across the value chain. The new features also complement existing services, such as fiber certification, application for product licenses, and branding materials.

Lenzing E-Branding Service adds multiple online service offerings in latest upgrade to offer greater convenience to value chain partners and brands

New features include Artwork Approval, Fiber Blending Quick Check Tool, Onboarding Tool, E-Branding Master Class and E-Branding Helpdesk

“Since the introduction of Lenzing E-Branding Service in 2018, we have been on a mission to pioneer the digitalization of value chain management. While we remain committed to providing unprecedented traceability across the industry value chain, ensuring better user experience remains the key foundation of the Lenzing E-Branding Service,” said Harold Weghorst, Vice President of Global Marketing and Branding at Lenzing AG. “With our latest upgrade, users can leverage the new Artwork Approval process to access licensed marketing or co-branding materials with a few clicks, and learn about our service offerings via a suite of comprehensive resources. While material verification during the production process is important, we will not stop there. We aim to extend such verification services to finished garments, enabling greater traceability along the value chain.”

Artwork Approval process offers greater efficiency for brands and retailers

As more consumers become aware of greenwashing, there is a growing need for brands and retailers to enhance descriptions of the sustainability elements in their products. Since 2017, the number of applications for fabric certifications, product licenses and swing-tickets in the E-Branding Service platform has grown exponentially, by around 1.5 times annually. To address the growing need for co-branded marketing content, the “Artwork Approval” process was launched to ensure fast turnaround for artwork confirmations. With a structured online collection of approved artworks, users can access their artwork collection anytime, anywhere, and apply selected artwork for multiple license applications.

Fiber Blending Quick Check Tool ensures effective labelling

To ensure accurate labelling of product ingredient, fabric manufacturers can leverage the new Fiber Blending Quick Check Tool to easily check whether the planned fiber blend of a specific fabric is in accordance with Lenzing’s Certification Standards. The tool can also verify the correct Lenzing fiber brand for each fiber type, which significantly helps retailers promote the final product among consumers. The Fiber Blending Quick Check Tool can be found on the landing page of the E-Branding Service. It is accessible to all visitors to the platform and does not require one to register.

Onboarding Tool, E-Branding Master Class and Helpdesk double up on knowledge transfer

To support the increasing number of users from different regions, the new E-Branding Service Onboarding Tool features a series of step-by-step guides that advises users on how to use the platform’s features. The recently launched E-Branding Masterclass also enables users to expand their knowledge of the platform through live webinars and recorded self-study learning modules covering certification and licensing of Lenzing’s TENCEL™, VEOCEL™ and LENZING™ ECOVERO™ brands. The self-study learning modules are available in English with subtitles in 10 languages. The E-Branding Masterclass is supplemented by the E-Branding Helpdesk service which provides users with live support from a dedicated team of Helpdesk specialists, creating a comprehensive knowledge sharing platform.

The Lenzing E-Branding Service Platform can be accessed via:

https://brandingservice.lenzing.com/en/login.