#Yarn & Fiber

Lenzing’s performance impacted by historically difficult market environment

- Fiber prices and demand under pressure due to COVID-19 crisis

- Measures to maintain operations and to protect employees, customers and suppliers implemented successfully

- Hygiene competence center established to produce personal protective equipment in the fight against COVID-19 pandemic

- Strategic investment projects in Brazil and Thailand progressing according to plan

- Management Board proposes not to distribute a dividend for 2019 – AGM rescheduled for June 18, 2020

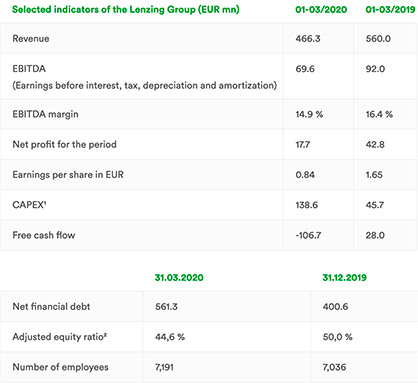

In the first quarter of 2020, revenue declined by 16.7 percent in comparison with the prior-year quarter and amounted to EUR 466.3 mn. The main reason was the development of prices for standard viscose (due to significant overcapacity in the market) and other standard fibers. The impact of the COVID-19 crisis further increased pressure on prices and volumes. The prices for standard viscose dropped to a new all-time low of 9,150 RMB/ton by March 31 – up to 33 percent lower than in the prior-year quarter. The comparatively positive development of the specialty fiber business and slightly higher demand for fibers in the medical and hygiene segments partially offset the decline in revenue. The share of specialty fibers increased from 47.3 percent in the first quarter of the previous year to 60.9 percent. The earnings development reflects the decline in revenue: EBITDA (earnings before interest, tax, depreciation and amortization) decreased by 24.3 percent to EUR 69.6 mn. The EBITDA margin declined from 16.4 percent to 14.9 percent. Net profit for the period was down 58.6 percent to EUR 17.7 mn. Earnings per share amounted to EUR 0.84 compared with EUR 1.65 in the first quarter of the previous year.

“The COVID-19 crisis has a severe impact on the entire textile and apparel industry and has further increased the pressure on prices and volumes in the global fiber market. Lenzing held its ground in this extremely difficult market environment and continues to drive the implementation of its key projects in Brazil and Thailand”, says Stefan Doboczky, Chief Executive Officer of the Lenzing Group. “To meet the strong demand for hygiene and protective products for the population and for medical personnel, we intensified the collaboration with partners along the value chain in the first quarter of 2020. Today we are proud that we have achieved our goal of an industrial production of high-quality protective masks together with our partner Palmers and have therefore been able to support Austria and Europe in combating the pandemic as best possible”, says Doboczky.

Strengthening specialty fiber growth

CAPEX (expenditures for intangible assets and property, plant and equipment and biological assets) more than tripled to EUR 138.6 mn in the first quarter of 2020. This increase is a consequence of the progress of the major projects in Brazil and Thailand. The implementation of the two most important long-term investment projects to strengthen internal pulp supply and to increase the share of specialty fibers in line with the sCore TEN corporate strategy is progressing according to plan. After the decision to build the dissolving wood pulp plant in Brazil with a capacity of 500,000 tons, the Duratex Group acquired a 49 percent share in the joint venture LD Celulose as agreed in the first quarter of 2020. Lenzing holds 51 percent of the shares.

In the first quarter of 2020, Lenzing completed the second pilot production plant for its TENCEL™ Luxe branded filament yarn. The new facility at the Lenzing site with a total investment of EUR 30 mn provides sufficient capacity for the development of commercial programs and further fiber applications.

Stand up! Against business as usual

On March 21, Lenzing presented its Sustainability Report 2019, which was also the International Day of Forests. The report sets out how the company is actively dealing with the global challenges. Under the motto “Stand up! Against business as usual”, Lenzing emphasizes its wider responsibilities over and above its products. With the implementation of the science-based target, Lenzing actively contributes to mastering the problems caused by climate change. The Lenzing Group is committed to reducing its greenhouse gas emissions per ton of product by 50 percent by 2030 (baseline: 2017) and to become climate-neutral by 2050.

Production of high-quality protective masks: Hygiene Austria LP GmbH

Lenzing intensified its collaboration with partners along the value chain in the first quarter of 2020 to meet the increased demand for high-quality hygiene and protective products. In late April, Lenzing AG and Palmers Textil AG founded “Hygiene Austria LP GmbH”, in which Lenzing AG holds 50.1 percent and Palmers Textil AG 49.9 percent. The newly founded company started producing and selling protective masks for the domestic and European markets from May 2020. The two companies invested several million euros in a modern production infrastructure at the Wiener Neudorf location and secured the corresponding raw materials for protective masks production. In a first step, the company produces so-called mouth-nose protective masks (MNS) and surgical protective masks of class EN14683. Hygiene Austria LP GmbH plans to increase its capacities to over 25 million masks per month and to expand this business geographically as well.

Virtual Annual General Meeting on June 18, 2020

The Lenzing Group’s 76th Annual General Meeting has been rescheduled for June 18, 2020 after it was postponed on March 17 against the backdrop of further measures taken by the Austrian government to contain the coronavirus. The Management Board of the Lenzing Group reassessed its original resolution for a dividend distribution of EUR 1.00 and decided to propose to the Supervisory Board and the Annual General Meeting not to distribute a dividend for the 2019 financial year. The proposal not to pay out a dividend is supported by B&C, the majority shareholder of Lenzing AG.

Guidance for 2020 remains suspended

The Lenzing Group suspended on March 24 its result forecast for 2020 as a consequence of the COVID-19 crisis.

For 2020, the International Monetary Fund currently projects the greatest recession of the global economy in the course of a century. Global economic output is expected to contract by 3 percent in 2020, while a decline by 6.1 percent is anticipated for the advanced economies.

The impact of the COVID-19 crisis on the business of the Lenzing Group can still not be reliably estimated and strongly depends on the duration of the crisis and its impact on the global economy and textile markets. Consequently, the guidance for 2020 remains suspended.

The comparatively solid business development in the first quarter reassures the Lenzing Group in its chosen corporate strategy sCore TEN. Lenzing will continue to implement its strategy with great discipline with a particular focus on the strategic investment projects which both will yield to a significant contribution to earnings starting from 2022.