#Weaving

Advantages of yarn intermingling for weaving and warp knitting

Heberlein offers a unique retrofit to deliver air savings and more

High-speed weaving and warp knitting processes demand yarns with smooth surfaces for efficient processing. Special procedures to achieve the required yarn quality include air interlacing and sizing. With sustainability in mind sizing is less favoured, since the sizing agent has to be removed after weaving using water and creating high pollution loads.

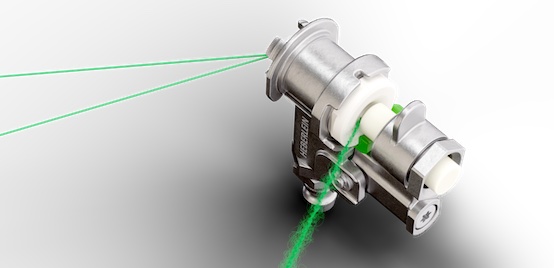

The art of air interlacing

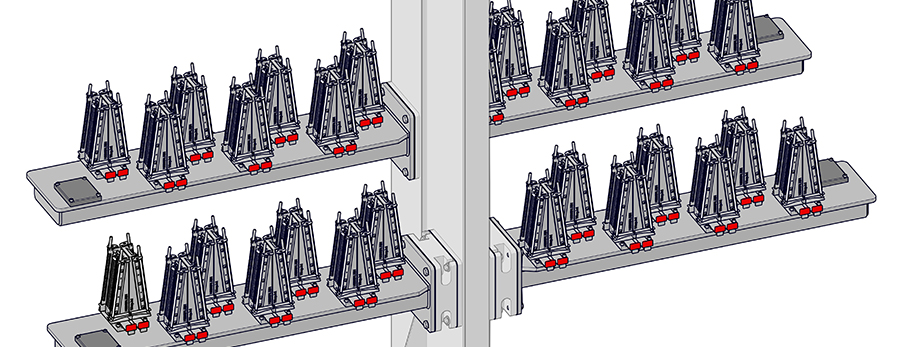

To develop a novel interlacing system, Karl Mayer, the leading manufacturer of preparation systems for warp knitting and weaving, turned to Heberlein. As a reputable name in filament yarn processes, Heberlein’s competencies in air jets made it an ideal partner. Their collaboration in 2015 started to innovate a completely new air interlacing system that gives considerable economic advantages in warp preparation and the subsequent fabric production sequences.

A process creating reliable intermingling points has several benefits, as the weaving machine no longer stops through shedding issues with filament openings or friction from broken filaments. So, the weaving process runs at higher speeds, also enabling size application to be reduced.

Heberlein’s high-precision components can be used when the process needs maximum efficiency and yarn strength. The WarpJet-KV can increase the intermingling points to 60 to 90 per metre – about triple the usual number, to suit individual requirements in the weaving process. Common speeds from 4,500 to 5,000 m/min in the spinning process usually allow 15/30 nips per metre, which might be sufficient for a smooth weaving process. However, many mills prefer to be on the safe side, especially when using yarns of ? 75 denier and DPF ? 1.0 – so they opt to install the Heberlein intermingling device.

Less air, more profit

The other key aspect is the air pressure needed to guarantee an increased number of intermingling points to assure filament cohesion, especially with fine yarns. During air interlacing, an air blast physically intermingles the individual filaments of a multi-filament yarn with one another.

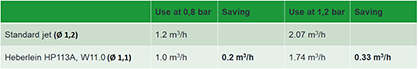

Saving compressed air in the air interlacing process results in less energy costs. This is proven with the Heberlein WarpJet-KV. Tests at the same machine with 1,536 threads – and using the same level of air pressure – show that compared with a standard jet the WarpJet-KV allows savings of 307 and 491 m3/h. Comparing the air pressure needed for the same amount of intermingling points (FP/m) the savings add up to 38%. Thanks to advanced technology by Heberlein, the diameter of the jet’s air orifice is smaller and requires less air while producing the same number of knots.

Never too early for profitable investment

In warp knitting, the demands are stringent and complex. Uncompromised yarn quality with highest production efficiency at lowest cost – with the premise of sustainable production – is fundamental. That makes it an ideal time for a retrofit with a proven solution: the Heberlein WarpJet-KV. The figures show interlacing performance up to 10 to 30% higher than competitor jets, based on the same air consumption and stability requirement of intermingling points. Air consumption can be 13 to 40% lower for the same number of intermingling points.

Karl Mayer machines can be retrofitted to install Heberlein’s WarpJet-KV with a modification of the main air connection. The modular design of the jets allows up to 64 yarns to be interlaced in a single unit. Depending on the application, customers benefit from the easy exchange of the JetPack and – typically with Heberlein jets – maintenance, cleaning and replacement are easy.