#Weaving

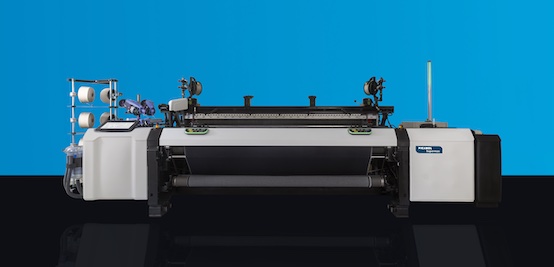

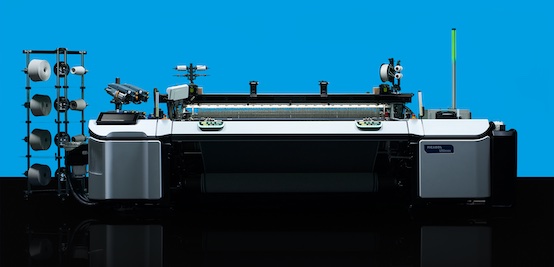

Picanol introduces the Terryplus-i, the new benchmark in terry weaving

“The latest terry technology makes the new TerryPlus-i the most performant and versatile terry machine on the market. It doesn’t matter if it is high pile, low pile, high density, low density, complex styles, or simple styles - this machine can handle any challenge. In order to realize this versatility we have developed a completely new pile formation system where the user can program any pile height between zero and twelve millimeters, regardless of whether it is plain terry, wave patterns, or any other pattern and this is done on a pick-by-pick basis,” explained Johan Verstraete (VP Weaving Machines).

Furthermore, thanks to the unique pile motor set-up directly driving the cloth and backrest movement simultaneously, accurate pile formation is assured at the highest speeds. The unique pneumatical pile backrest ensures optimum loop formation regardless of fabric design. The rigid yet extremely light construction ensures a highly dynamic behavior, guaranteeing perfect loop formation for even the most complicated terry designs - be it very light towels or heavy bathmats. Put simply, this is by far the best pile compensation system ever!

Special attention was given to ease of use thanks to a completely new human-machine interface. The new display measures 15.6 inches and it is equipped with all of the functionalities you are familiar with from your smartphone: touch, swipe, and the latest connection possibilities: ethernet, USB, Wi-Fi, Bluetooth, and Near Field communication (NFC – this is the technology we use when making contactless payments).

The TerryPlus-i comes with two possible prewinders: the Blue 22 and the Blue 11 (the one with separate windings). Both are equipped with the easy set function which manages all settings electronically through the display. Consequently, there is no longer any need for tools or special keys to tune the prewinders. And all of this can be done without having to stop the machine, which enables you to optimize and reduce the waste length to an absolute minimum.

An additional groundbreaking novelty is PosiJet, which comes in a four channel version and positions each main nozzle exactly in line with the reed on insertion. This means that there is only one setting for all four nozzles and no need for a reed with a conical entrance. The result is savings in terms of both time and costs (this is because these conical reeds are quite expensive).

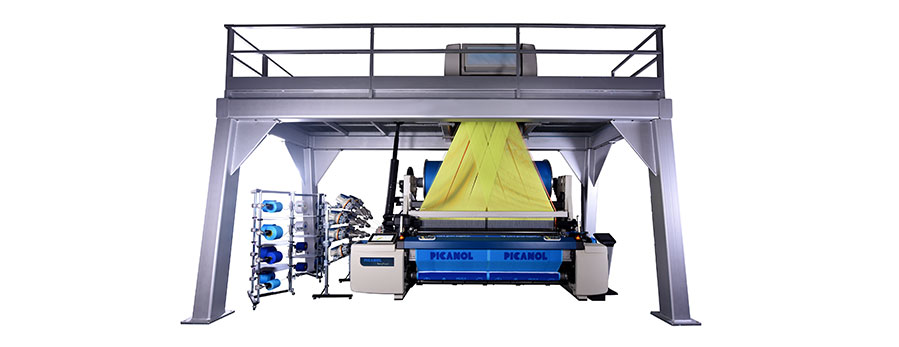

The range of possible shedding motions - dobby and jacquard - has been completed with SmartShed for independent and individual shedding motion. SmartShed has been developed for those weavers who want to maximize digitization and flexibility in their weaving processes. The movement and the crossing of the harness frames is actuated individually for each frame by a separate motor and it is set fully electronically. This will facilitate the optimal setting whenever you are weaving a simple three pick terry or a more complex seven or nine pick terry.

For more information, please download the app at www.picanol.be/app or follow us on http://www.picanol.be.