#Weaving

Itematech will showcase the most comprehensive weaving solutions to weave technical fabrics at Cinte TechTextil 2020

Itematech is the brand-new Technical Division exclusively dedicated to producing weaving machines for the benefit of technical fabrics weavers launched in 2019 by Itema, the Italian leading global provider of advanced weaving solutions, including best-in-class weaving machines, spare parts and integrated services. The strategic alliance between Itema and PTMT (formerly Panter) leads to a complete and never-before-seen product portfolio, which ranges from negative and positive rapier, to air-jet and projectile weaving machines. Thanks to the strong know-how resulting from the merger of the two historic weaving manufacturers expertise and competences, technical fabrics manufacturers will now on find in Itematech a unique partner and technological reference point to meet and exceed all their needs when it comes to weaving the full range of technical applications.

Mr. Paolo Pezzoli, Itematech Sales Director, comments: “As a partner and weaving machinery supplier to textile manufacturers worldwide, at Itema we strongly believe in the endless opportunities and the growth potential of technical applications, that represent a consistent and growing portion of our annual overall turnover. China is a strategic area, along with Asia in general, where the adoption of our technology for technical textiles is on the rise. A significant number of weaving machines by Itematech are used for technical textiles, like geotextile, coating, filter fabrics to list just a few applications”.

During Cinte Techtextil, Itematech team will concentrate in showcasing the company strong offering for technical fabrics weavers. Itema is uniquely positioned to offer technical textile manufacturers the top three weft insertion technologies – Positive and Negative Rapier, Airjet and Projectile, in what is the most comprehensive portfolio on the market today for technical applications.

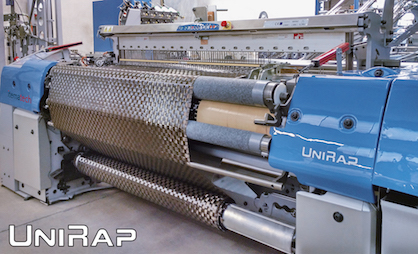

Unirap Single Positive Rapier Weaving Machine

UniRap, Itematech Single Positive Rapier Machine, embodies versatility and provides endless weaving possibilities. Combining the advantages of a positive rapier weft insertion with the gentle yarns treatment ensured by the free fight transfer system, UniRap enables complex and creative fabrics weaving with practically no limitations and maximum textile efficiency. Ranging from refined lamè to high tenacity monofilament yarns, passing through bouclé yarns up to carbon, polyester and polypropylene tape, UniRap provides the possibility to weave sophisticated technical fabrics and innovative fashion styles.

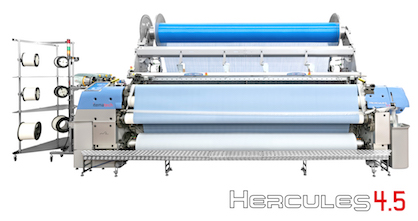

Hercules Positive and Negative Rapier Weaving Machine

Hercules is a Positive and Negative Rapier Weaving Machine designed to excel in technical textiles weaving. Offering both negative and positive rapier transfer systems, Hercules represents the perfect combination of mechanical sturdiness and textile efficiency ensuring the greater profitability in the market for applications such as Agrotextile, Heavy and Standard Coating Fabrics, Conveyor Belts and Filter Fabrics, Fiberglass, Geotextile, Mesh Fabrics and many others.

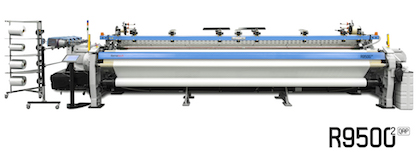

R95002 Rapier Weaving Machine

R95002 Rapier Weaving Machine is known to be the most positive negative rapier machine in the market, due to the uniqueness of its weft transfer system which provides unparalleled versatility of yarns and patterns. The continuous roll-out of customized special versions tailored for technical applications, including OPW Airbag, Fiber Glass, Bolting Cloth, among others, the wide weaving width up to 540 cm, as well as new and advanced devices make the R95002 by Itema the perfect machine to weave the full range of technical textiles, including ones with the finest monofilament, multifilament high tenacity yarns, and multiple pick insertion fabrics.

P7300HP Projectile Weaving Machine

Technical fabrics are the specialty of the legendary and unique P7300HP Projectile Weaving Machine due to the unparalleled versatility and reliability of its weft insertion system. The unmatchable uniqueness of the positive weft transfer consists in the single insertion driven by the projectile, which catches the weft and carries it directly with no exchanges, providing unmatched efficiency.

The P7300HP continues to harness great interest from projectile weaving aficionados and represents an unbeaten and unbeatable benchmark for those looking to weave the widest fabrics – up to 655cm weaving width – and high-specialty materials, such as agrotextile, geotextile and carpet backing. When it comes to weaving tape yarns, the Itema projectile weaving machine provides the highest performance compared to all the other insertion technologies currently available on the market.

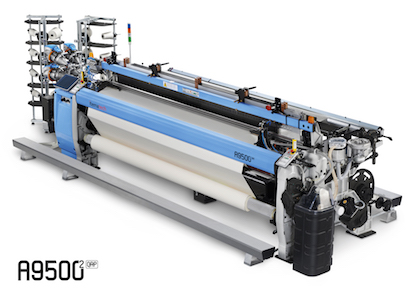

A95002 Airjet Weaving Machine

When it comes to weaving very high-density fabrics A95002 Airjet Weaving Machine is customized with dedicated devices to ensure best-in-class results. Key components are reinforced to ensure optimized machine control and reliability whilst reducing consumption and assuring superior textile efficiency.

To discover the Itematech innovations for technical fabrics and the utmost Customers’ dedication, make sure to visit the Company stand at Cinte Techtextil (Hall E01 – Stand E1).