#Weaving

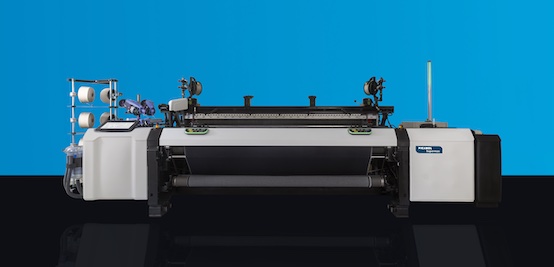

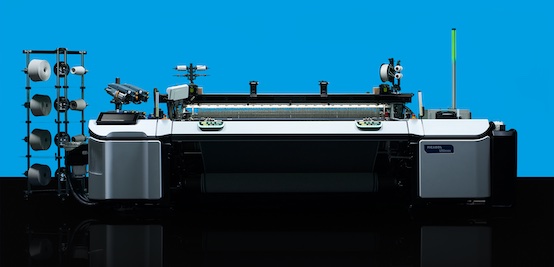

Picanol shows brand new OmniPlus-i at ITMACH India

This machine further builds on the solid base of nearly 40 years of experience in airjet weaving, during which over 100,000 airjet machines have so far been shipped. The OmniPlus-i that will be on display at ITMACH India will be a 220 cm machine weaving a denim fabric at the highest industrial speeds. The Picanol booth will be located in the Weaving Hall A1/2/3/4.

“India is a market that is of crucial importance to Picanol as it is one of the world’s key textile markets. We are therefore very proud to be able to demonstrate our latest airjet machine, the ?OmniPlus-i, to our Indian customers for the very first time. The new OmniPlus-i features a redesigned reed motion, optimized relay nozzle set up, and it can be combined with SmartShed, the full electronic controlled shedding motion,” commented Johan Verstraete, Vice-President Weaving Machines. “We have been successfully serving the Indian market since 1956 and in light of the potential and expected growth of the Indian market, we decided to set up our own organization in India in early 2008. The aim behind this move was to ensure that we could more actively support our Indian customers. With the broadest product range on the market in both airjet and rapier weaving machines, improved local services and considerable presence, we remain highly committed to the Indian market and it is our ambition to further reinforce our position as the leading provider of weaving machines for the entire Indian textiles sector.”

Strong presence in India

In addition to its main office in Delhi (which also includes an electronic print repair shop), the regional offices in Mumbai and Coimbatore are clear proof of Picanol’s strong presence in the Indian market. In total, a team of 35 Picanol professionals in India are committed to providing outstanding service to its customers.

Offering the most complete range in weaving technology

Picanol considers that in this fast-changing world of weaving, the needs of weaving mills in general and the expectations of its customers and their operators are evolving rapidly. Nowadays, its market is driven by an increasing concern for environmental topics, higher costs, and lower availability of resources and skills, as well as the digital revolution that is affecting all industries.

Picanol has always been a pioneer in regard to offering the latest weaving technology, and it has the most complete range in weaving technology available on the market. The Picanol airjet machine portfolio comprises the new OmniPlus-i, OMNIplus Summum, TERRYplus Summum and OMNIplus 800 TC machines, which combine heritage with a clear vision of the future. Meanwhile, for versatile and productive rapier weaving, Picanol offers a broad range of weaving machines with its unique, future-oriented OptiMax-i flagship product, GTMax-i 3.0, GTMax-i, and GT-Max.