#ITMA 2019

SANTEX RIMAR GROUP and SMIT, at ITMA Europe

“Santex Rimar Group will once more demonstrate his unique capability to understand customers’ needs along the complete production process in textile industry, testified by the impressive machinery and processes innovation presented at the exhibition, from weaving to finishing

to technical textiles, exploiting areas where real added value can be transferred to its valuable customers” says Ferdinando Businaro, Santex Rimar Group President.

“Santex Rimar Group aims to transfer the results of tireless research and improvements to the customers in order to give them unique competitive advantages, supporting them in the race to be really sustainable and successful” concludes Simone Rancan, Group CEO.

NEW PRODUCTS:

Sperotto Rimar COMPAS

The Compacting Revolution

New frontier in compacting woven and knitted fabrics made in natural and blended fibers

Solwa DRYWA

Green sludge dryer

Efficient and cost-effective sludge management respecting environment and climate

Santex Rimar Group ATHENA

Advanced Deep Learning Technologies

Achieve quality production standards with Industry 4.0

NEW PRODUCTS:

Smit 2FAST

Flexible Advanced Shuttleless Technology

Unleash the full potential of free flight

Santex Rimar Group GUARD ONE

Quality control system

Protect your profitability and production consistency

Santex Rimar Group 2SAVE

Sustainability through fabric waste reduction

During the tradeshow it will be possible to meet our staff at the booth and see some of our best-seller products:

Hall 2 | C106

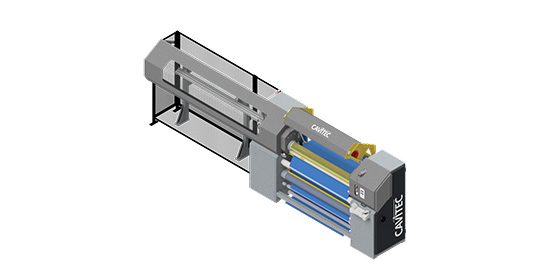

Cavitec CAVIFLEX

Hotmelt coating and laminating machine with interchangeable coating modules

Isotex ISOCOAT

Highly customizable coating and laminating lines for technical textiles

Santex SANTACOMPACT RD

Felt belt compacting for the high-quality finishing of open width knitted fabrics

SperottoRimar DECOFAST 4.0

The evolution of continuous decatizing process under pressure equipped with a new high-performance steam extraction system

SperottoRimar VELURA DD28

The latest and most advanced solution in the raising technology

Hall 4 | D107

Smit GS980 260 F8 J

Combined with a 6.144 hooks STAUBLI Jacquard (full width, 1 hook per end, 12+12 ends/cm), with 100% cot- ton, dyed yarn terry towel

Smit GS980 360 C8 J

Combined with a 27.648 hooks BONAS Jacquard (full width, 1 hook per end, 79,5 ends/cm), with 100% cotton bed sheeting

Smit GS980 220 C8 D

With synthetic sportswear article, multifilament black and white polyamide warp yarn, 44 ends/cm; texturized polyamide weft yarn, 32 ins/cm

Smit ONE 190 C8 J

Will be on show in combination with a BONAS Jacquard and the Van De Wiele “Smart Creel” at Van De Wiele booth (Hall 4, stand A206)