#Textiles & Apparel / Garment

Cooling textiles as a game changer: E.COOLINE triumphs at the German Sustainability Award

Climate adaptation for a heat-resilient future

Rising temperatures are threatening the health and productivity of millions of people worldwide. Studies show that extreme heat not only affects well-being but also poses serious health risks and can lead to significant productivity losses and deaths. The need for functional adaptation strategies is therefore constantly growing in order to strengthen the resilience of all people in cities and communities as well as companies to the consequences of global warming. According to the LANCET, 37 million working hours were lost due to heat in Germany alone in 2023. In addition, the number of heat-related illnesses is constantly increasing.

Therefore, simple, effective and affordable cooling is becoming more and more important – for some people it is now even essential for survival. However, according to the German Environment Agency, 120 to 130 million air conditioners and cooling devices are sold each year, which already consume 8% of the world's energy and emit 1 gigatonne of CO2. With fatal consequences. Because what can protect health and sometimes even save lives is becoming a disaster for the climate. The solution: E.COOLINE! The brand with the high-performance COOLINE SX3 technology is the sustainable solution for escaping this vicious circle. That is why the DNP jury is enthusiastic about this game changer and has declared E.COOLINE the winner in the “Climate” category.

Cooling textiles as a smart answer to the heat

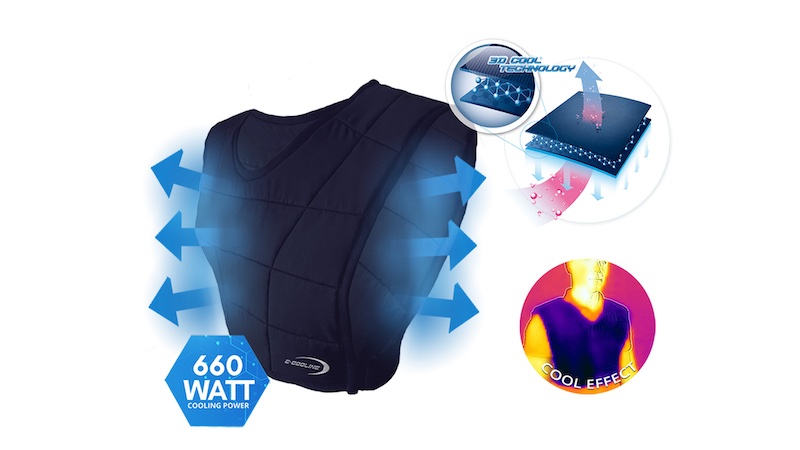

The actively cooling functional textiles – including cooling vests, cooling shirts, cooling headgear, but also cooling home textiles for room cooling – are the simple, immediately usable and cost-effective alternative to air conditioning, which works both indoors and outdoors! With up to 660 watts of cooling capacity, they cool people and animals in an environmentally and climate-friendly way. No external energy is required for this - the cooling effect is created bionically by water and air.

This innovative technology is no longer a vision of the future: it is already being used successfully in the world of work, in sports, as well as in medicine and leisure, and is becoming increasingly important for preventing health risks, heat-related deaths and productivity losses in a warming world.

Health protection and environmental awareness combined

“We are incredibly proud of this award,” says Gabriele Renner, managing director of pervormance international GmbH, who developed E.COOLINE together with her sister Sabine Stein, thus setting innovative impulses for change. ”Our cooling textiles are much more than just a climate product. They are a direct response to the increasing health risks caused by heat. They make living and working spaces heat-resistant and protect health.” Compared to air conditioning systems, E.COOLINE products can save up to 97 percent of CO? emissions. ‘The fact that our products have now been officially recognized as pioneers in health and climate protection shows how valuable this technology is for a future worth living,’ emphasizes Sabine Stein.

The company behind the E.COOLINE brand

The E.COOLINE brand is owned by pervormance international GmbH, a German company based in Ulm that specializes in sustainable air conditioning. The entire E.COOLINE technology is developed and produced in Germany. In order to further reduce the ecological footprint, the fabrics and materials are produced in Germany and Europe to keep transport distances as short as possible. The high-tech fleece is made from upcycled waste fibers, and the products can be recycled. Green electricity is used at the pervormance international headquarters. In addition, the company is involved in the UN Global Compact, the Senate of the Economy, the Textile Alliance and the Alliance for Development and Climate. For its sustainable commitment, the company has already been awarded the Sustainable Impact Award (SIA) by WirtschaftsWoche, the Climate Protection Prize of the Senate of the Economy and the Brand Manager Award in the field of ecology by the HNU.

E.COOLINE shows how a positive difference for health and climate can be made through innovative, climate-friendly cooling.