#Textiles & Apparel / Garment

Teijin Frontier develops new functional fabric featuring unique span-like texture and high stretchability

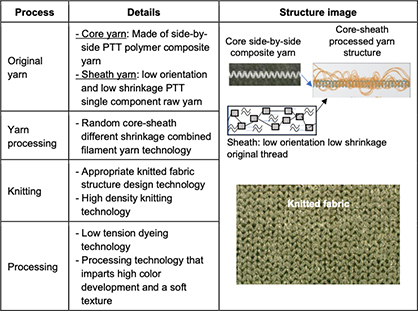

SOLOTEX® LIBERTE uses polytrimethylene terephthalate (PTT) fiber featuring a proprietary low-shrinkage technology and a distinctive yarn processing method that maximizes the properties of PTT while controlling the raw yarn’s heat shrinkability. Specifically, this product uses side-by-side composite yarn (*), which Teijin Frontier cultivated with its variety of SOLOTEX® stretch fabrics, that combines PTT polymer as the core yarn with newly developed low-orientation, low-shrinkage PTT monocomponent as the sheath yarn. The result is a blended yarn with two different shrinkage properties. After the core and sheath yarns are randomly mixed using fiber processing technology, they are knitted using high-density knitting equipment.

Technical details for SOLOTEX® LIBERTE

*Side-by-side composite yarn achieves high stretchability by laminating two types of polymers with different heat shrinkability characteristics to form a coil-like crimp structure.

SOLOTEX® LIBERTE fabric features a soft texture and smooth finish. It also provides beautiful aesthetics, including vivid colors and a luxurious matte glossy appearance. The material has a high silhouette with a moderate drape. Apparel made with SOLOTEX® LIBERTE provides comfort, thanks to its soft stretch, light weight, water absorption and quick drying properties.

Material requirements for sportswear and casual wear are becoming more sophisticated. In addition to superior texture and appearance, consumers are demanding exceptional comfort and lower environmental impact. Teijin Frontier’s SOLOTEX® fiber delivers soft, smooth fabric with an attractive appearance, and supports sustainability by using approximately 40 percent plant-derived raw material.

SOLOTEX® has variety of lineups such as stretch fabrics using side-by-side composite yarn and soft and smooth fabric with colorability using PTT monocomponent taking advantage of PTT fiber’s characteristics. Teijin Frontier has been widely promoting SOLOTEX® in the global market and also developing fabrics that make the most of its characteristics, however, it could not achieve excellent stretchability and sufficient swelling at the same time due to the difficulty in controlling the heat shrinkage of PTT polymer.

Teijin Frontier will begin promoting SOLOTEX® LIBERTE globally for the autumn and winter 2024 collections of sportswear and casual wear. The company expects sales of SOLOTEX® LIBERTE to reach 500,000m by fiscal 2026.