#Textile chemistry

BASF redefines the future of the footwear industry with its first global Footwear Innovation Center in Taiwan

- New facilities to bolster BASF’s global network of footwear development centers

- Features include interactive footwear exhibits, biomechanics lab and manufacturing facilities to boost footwear design capabilities

- Interactive zones enable brands and molders to select footwear materials and improve manufacturing processes

The 7,000 square-foot Center is an immersive environment where BASF can help various brands to drive footwear transformation. This one of a kind space highlights BASF’s revolutionary footwear materials, innovative culture, and the latest footwear manufacturing technologies from LTC to fulfill innovative footwear design needs.

“Taiwan is Asia’s hub for many footwear manufacturing firms and has a longstanding history with a powerful network of designers. Differentiation is the core ingredient needed to win in the footwear industry. We are committed to constantly innovating and co-creating with our customers. The Footwear Innovation Center offers footwear customers an immersive and collaborative experience to co-create innovative components, processing, and solutions together,” said Andy Postlethwaite, Senior Vice President, Asia Pacific, Performance Materials, BASF. “Also, the center will provide our strategic partners and customers with direct access to advanced technologies and high-performance materials in one place, helping them advance in the footwear market.”

Global collaboration and material innovation help brands unlock growth potential for footwear solutions

Combining LTC’s latest footwear manufacturing technologies with BASF’s material expertise in footwear, the center will enable brands to address common operational challenges, optimize manufacturing processes, and improve efficiencies. The new facility will also test and refine material innovations within a shorter timeframe, as well as evaluate concepts on a global scale. A previous collaboration between BASF and LTC on X-Swift – an athleisure shoe that showcases five BASF’s advanced material innovations – was also made possible through a fully connected footwear manufacturing facility from LTC.

Offering footwear material and manufacturing solutions under the same roof

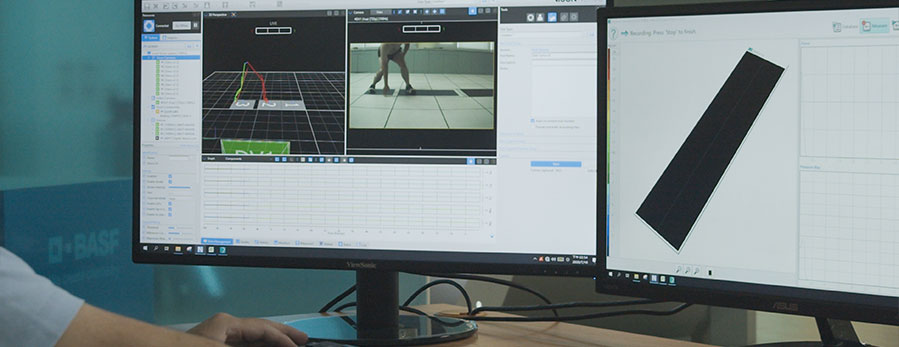

The Footwear Innovation Center will also house a biomechanics lab, where scientific tests will be conducted to develop new footwear solutions that enhance performance, comfort, and improve athletic performance.

The Footwear Innovation Center includes three main zones:

The Design Zone – an interactive display area of performance materials and artworks that stimulate footwear design processes. This area features two of BASF’s performance materials. Haptex™ is a low-emission synthetic leather that contains zero solvents, offers design freedom, and production efficiency for shoe uppers. Freeflex™, a thermoplastic polyurethane (TPU) fiber made with Elastollan®, unlocks limitless design potential for knitted uppers.

The Functional Zone – an immersive zone to stimulate visitors to create forward-thinking footwear solutions for the industry. It features a wide range of materials, such as Elastopan®, and Polyurethane (PU) solutions that allow vast possibilities of customization, excellent technical support, and the next level of performance. Infinergy®, the expanded Thermoplastic Polyurethane (E-TPU) that revolutionizes the performance footwear industry, is now available for safety and dress shoes. Forward AM, a BASF brand specialized in 3D printing, amongst others produces the materials Ultrasint® TPU powder and Ultracur 3D® EL UV resin, which are ideal for 3D shoe printing due to their strong shock absorption and rubber-like elasticity.

The Creation Zone – an inspirational zone that showcases existing design works to encourage ideation and co-creation of breakthrough footwear solutions. It also features a sports flooring series made of Infinergy SP, a special grade of E-TPU from BASF, and a full PU impermeable structure certified by the International Association of Athletics Federations (IAAF). The center includes state-of-the-art footwear design software, in-house mold-making Computer Numerical Control machines, automated PU injection machines, and upper knitting machines that enable new shoe design possibilities.

“The launch of the Footwear Innovation Center is a milestone for the footwear industry in Taiwan and Asia, aimed at connecting brands, manufacturers, and designers. This will accelerate the adoption of the latest footwear technologies and materials to serve the industry better,” said Smith Shih, President, Longterm Concept Industry Corp.

BASF has three other Footwear Development Centers, located in Italy, the United States and Thailand. The Footwear Innovation Center will also complement the expertise and competences of the product development center in Chinese Mainland’s Shanghai and Nansha.