#Textile chemistry

Breathable water-based synthetics

Great design freedom in various applications

Covestro and Trans-Textil cooperate in textile coating

"The microporous structure of the synthetics is permeable to water vapor and provides the greatest possible comfort in combination with individually selected textiles", explains Matthias Krings, managing director of Trans-Textil. "In combination with other functional layers, products created on this basis are also characterized by their considerable freedom of design in terms of structure, coloring and technical properties."

Advantage polyurethane

"The polyurethane coating is particularly abrasion-resistant and breathable, but in combination with membrane systems from Trans-Textil it can also be made both waterproof and windproof," adds Thomas Michaelis, expert for coated textiles at Covestro. "It is built on our water-based and sustainable INSQIN® technology, which also means that the production of coated textiles requires up to 95 percent less water and 50 percent less energy than previous processes based on solvents." As a result, this technology was awarded the Solar Impulse Efficient Solutions label as an economically viable and environmentally friendly solution.

This combination of properties combined with Trans-Textil's extensive portfolio of membrane systems, textile substrates and technologies provides its customers with a very wide range of sophisticated and individual products. Options include embossed designs in classic or exotic leather looks, textile structures or technical patterns, flexible coloring and a wide selection of textile substrates and spacer systems based on woven, knitted or non-woven fabrics, with which AQUAIR® can be combined in functional multi-layer composites.

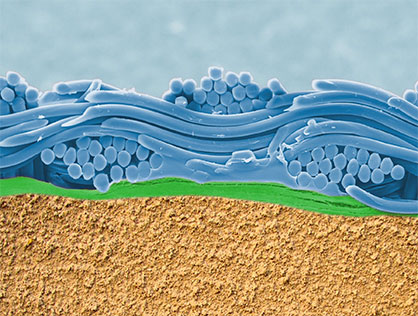

In combination with Trans-Textil's technologies, the entirely water-based and solvent-free polyurethane dispersions of the Impranil® and Impraperm® ranges developed by Covestro enable unprecedented breathable properties with a level of comfort and functionality that far exceeds the standard of coated textiles. Water-repellent properties are already integrated into the materials meaning that no additional finishing with harmful substances such as perfluorinated and polyfluorinated compounds (PFCs) is required.

Versatile use in shoes, outdoor, leisure, sports and furniture segments

AQUAIR® can thus be used to design shoe components, leisure, sports and outdoor clothing, bags and accessories, as well as upholstery and furniture. The flexible combination with other functional layers focuses on the requirements of the application as well as the technical and design demands of the customers even for small series or samples. The production as roll material is the basis for an optimal use of material in ready-made clothing.

As a shoe component designed to enhance comfort, the high water vapor permeability of AQUAIR® contributes to the active regulation of the microclimate inside the shoe. Its breathability is preserved even in combination with a waterproof functional membrane system, which Trans-Textil also offers as an option for purely water-based products. The washable technology ensures the greatest possible freedom of movement in clothing due to its high degree of elasticity. As covers for furniture, the products not only score highly for their abrasion resistance, but also in terms of reduced perspiration in the seat and backrest areas, stain resistance and easy care. AQUAIR® can also be laminated with upholstery foams if required. This results in textile-based multi-layer systems boasting high standards in terms of performance as well as ecology.

Reliable seam sealing

In addition, both partners have also developed solvent-free seam sealing tapes for all common laminate types. Topaz tapes provide reliable impermeability and enable long-lasting use of high-quality functional textile, for example in shoe laminates, work wear, outdoor, leisure and sportswear as well as in technical garments. The tapes can be customized in terms of technical properties, dimensions and design. They are designed for industrial washing at up to 60 degrees Celsius.