#Techtextil 2022

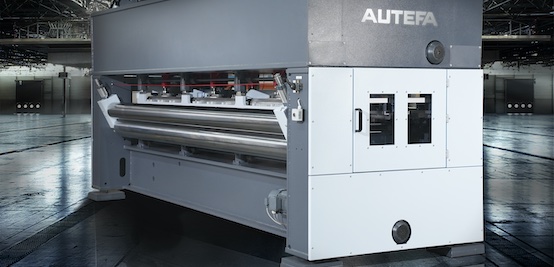

AUTEFA Solutions are committed to technology that is both innovative and sustainable

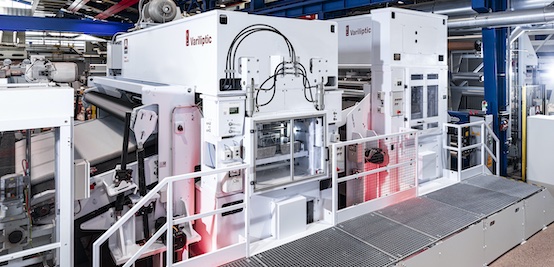

The general trend is for weight reduction whilst maintaining physical properties providing savings in material costs and increasing operating speeds. Customers require machines and lines that are able to produce light weight fabrics without any compromises regarding material strength. Furthermore, growth in needlepunching technology remains strong, a good example is Artificial Leather, also in terms of sustainability. AUTEFA Solutions serves the growing demand for needled technical applications e.g., the filtration business and for paper maker felts. Sustainability is a huge topic, worldwide. With the increasing environmental awareness, the demand for renewable textiles is forthcoming, allowing the wood pulp technology segment to grow enhanced growth rates. Our customers are increasing the use of replacement fibers like recycled PET fibres, carbon fibers, reclaimed fibers as well as various natural fibers such as hemp or coconut.

Therefore, AUTEFA Solutions needle punching have special options like optimized bed and stripper plates, advanced needle patterns with conical bed plate holes, and optimized feeding system for pre-needle looms. A dust extraction system is available and recommended when processing recycled and natural fibers, glass and short fibers, and carbon and mineral fibers.

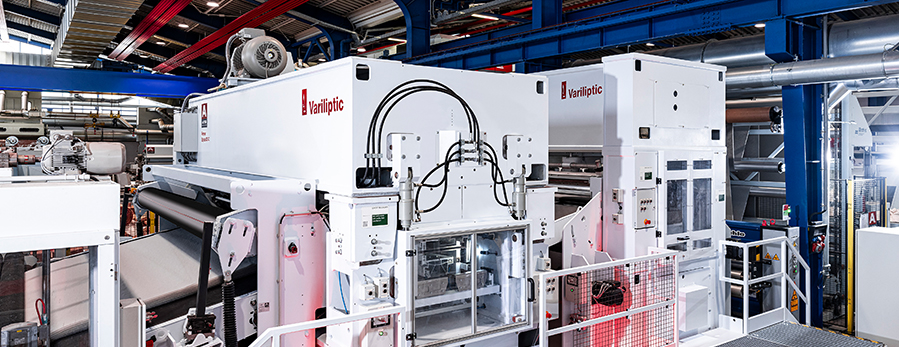

AUTEFA Solutions Needle Punching lines distinguish themselves by easy operation, less energy consumptions/gms, excellent and reproducible product quality with reduced operation cots. The needlelooms of the Stylus product family can process all fiber types. The needle looms are designed to suit the required output and speed by adjusting the number of the drive modules. AUEFA’s needlepunch lines produce an even and homogenous lightweight fabric with outstanding technical performance in terms of tensile strength and evenness (MD/CD ratio). Needle punching lines are composed by several steps, like blending, carding, crosslapping and needling. The performances of such a line and the quality of the product in terms of appearance, evenness and mechanical characteristics depends on all steps. As a full line supplier, AUTEFA Solution has worked on all the different steps of the process to improve the performances and supply high quality line on all its components.

AUTEFA Solutions offers a complete range of nonwovens machinery, covering needlepunch lines, aerodynamic web forming, spunlace and thermobonding equipment. Application sectors range from hygiene and wipes through filtration, geotextiles, automotive, carpets, technical felts, wadding and insulation. In the premium nonwovens segment, AUTEFA Solutions is renowned for the quality, durability and performance of its technology for both forming and bonding processes, incorporating the famous brands Fehrer, FOR and Strahm.

More information here: AUTEFA Solutions: Nonwovens

https://www.autefa.com/nonwovens